Pentatonic and Natalia Vodianova launch innovative face mask

Natalia Vodianova and Pentatonic unveil Masuku one, their new high-tech, sustainable mask design featuring state of the art filtration system and made in England

Matt Writtle - Photography

Design firm Pentatonic and entrepreneur and philanthropist Natalia Vodianova have launched Masuku, a new brand offering an innovative and sustainable face mask concept. Named after the Japanese word for ‘mask’, Masuku nods to the importance of the face mask in Asian cultures, where it is commonly worn as a sign of respect for the community’s health. Its initial goal to create an anti-pollution mask has acquired new urgency in this pandemic; and its inaugural product, Masuku One, combines cutting-edge technological innovation and a sleek design.

Natalia Vodianova and Masuku: the search for a sustainable face mask

Pentatonic’s CEO Johann Boedecker and Vodianova at the new state-of-the-art Masuku AirLab in Hellaby, South Yorkshire

Vodianova began to search for a sustainable alternative to everyday masks in 2016, which led her to connect with Pentatonic, a design and technology innovator whose projects have material research at their core. The studio has created objects from recycled smartphone glass, cigarette filters and e-waste, also working on objects and furniture designs with the likes of Snarkitecture and Pharrell Williams (most recently creating a recycled dining kit in collaboration with both).

‘Natalia and I first met in 2018; at that point she and her team had already scoped the mask market for sustainable suppliers,’ recalls Johann Boedecker, CEO and co-founder of Pentatonic. ‘But there was simply nothing out there that lived up to Natalia’s vision of a truly well-designed and absolutely environmental mask.’ The pair joined forces with the aim of reinventing the category ‘from the ground up’, and after two years of development, Masuku was born.

‘As living beings, we need air even more than water or shelter but, due to a rise of allergies, air pollution and increased risk of pandemics, it is quickly becoming a risk factor too,’ continues Boedecker. The team’s focus was to create masks that become an effortless essential in our lives, much like sunscreen and filtered water.

Masuku One: design and manufacturing

Masuku One in black

The Masuku One features a ‘spacer mesh’ fabric cover, made from 100 per cent recycled performance polymer and optimised for airflow. The material is heat-pressed into a shell-like shape and equipped with soft guard fabric on the side in contact with the skin. The ear-loops are also made from recycled materials, and feature four 360-degree joints for a personalised fit.

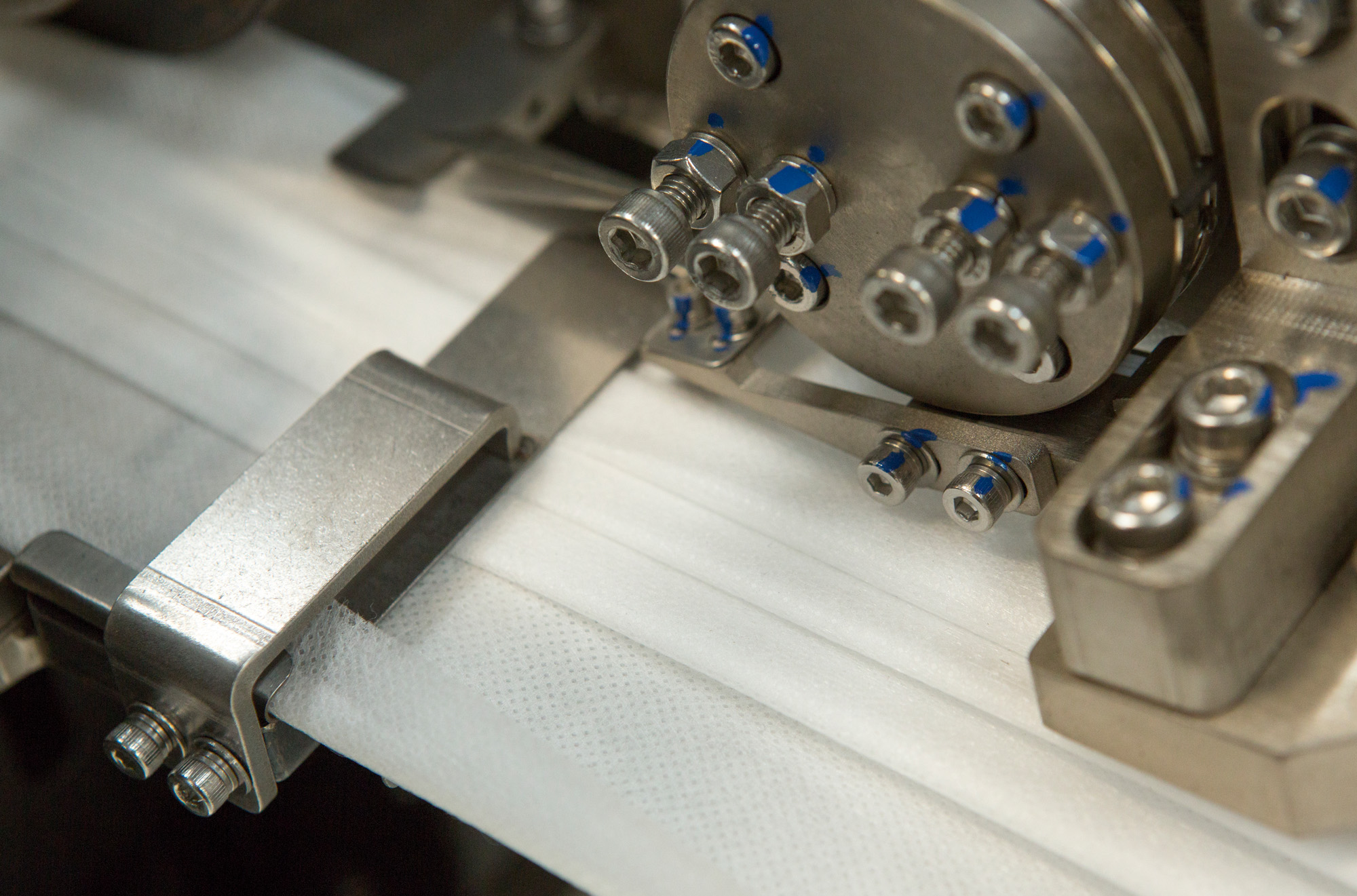

Every material is either bio-based or recyclable at the end of its life, and every manufacturing aspect was calibrated to achieve maximum comfort and carefully considered with sustainability in mind. ‘When I started the project, I knew that developing a highly sophisticated air filtration system was pointless if not fully sustainable at the core,’ explains Vodianova. ‘Today our masks offer a truly safe and comfortable breathing experience, with no impact on the planet.’ Boedecker notes that readily available recyclable filters did not offer an adequate performance, but ‘with our high-end compostable polymer filtration membrane we finally struck gold. We built the daily range and the Masuku One filter around that innovation: compostable filtration using over 100 times less filtration material by weight than common mask filters.’ To produce the masks’ nano-fibre filtration material, the company set up a state-of-the-art AirLab in Yorkshire, with further nearby locations dedicated to assembly and production of Masuku products.

RELATED STORY

The new state-of-the-art Masuku AirLab in Hellaby, South Yorkshire. The company’s revolutionary nano-fibre filtration material is produced under highly controlled conditions

‘Between the fit and comfort, filtration and breathability, we created a mask that you can wear for many hours a day without undue inconvenience,’ he continues. ‘We also invested a lot of time in creating very complex tooling to have three-dimensionally curved surfaces without creases or folds. So the outer fabric is beautifully contoured and sharp.’

Receive our daily digest of inspiration, escapism and design stories from around the world direct to your inbox.

Concludes Vodianova: ‘The air we breathe affects every organ and cell in our bodies. I sincerely hope, in the future, masks will not be needed. Until then, we want Masuku to be the most technological, sustainable option to breathe clean air, while respecting it.’

INFORMATION

Masuku One, £49 (£22 for monthly subscription)

Rosa Bertoli was born in Udine, Italy, and now lives in London. Since 2014, she has been the Design Editor of Wallpaper*, where she oversees design content for the print and online editions, as well as special editorial projects. Through her role at Wallpaper*, she has written extensively about all areas of design. Rosa has been speaker and moderator for various design talks and conferences including London Craft Week, Maison & Objet, The Italian Cultural Institute (London), Clippings, Zaha Hadid Design, Kartell and Frieze Art Fair. Rosa has been on judging panels for the Chart Architecture Award, the Dutch Design Awards and the DesignGuild Marks. She has written for numerous English and Italian language publications, and worked as a content and communication consultant for fashion and design brands.