Apple Watch Ultra 3 has innovation at its heart – a 3D-printed titanium case

We delve into Apple’s pioneering use of 3D-printed metal, and how it ties in with the company’s path to carbon neutrality

Receive our daily digest of inspiration, escapism and design stories from around the world direct to your inbox.

You are now subscribed

Your newsletter sign-up was successful

Want to add more newsletters?

Daily (Mon-Sun)

Daily Digest

Sign up for global news and reviews, a Wallpaper* take on architecture, design, art & culture, fashion & beauty, travel, tech, watches & jewellery and more.

Monthly, coming soon

The Rundown

A design-minded take on the world of style from Wallpaper* fashion features editor Jack Moss, from global runway shows to insider news and emerging trends.

Monthly, coming soon

The Design File

A closer look at the people and places shaping design, from inspiring interiors to exceptional products, in an expert edit by Wallpaper* global design director Hugo Macdonald.

Ambitious targets call for ambitious technology. Behind the scenes, Apple is making huge strides along the road to its stated intention of becoming carbon neutral across its entire footprint, from production to material use and packaging to distribution. For consumers, the most obvious manifestation of this Apple 2030 goal is the shift in packaging design to incorporate as much recyclable – and recycled – materials as possible.

Apple Watch Series 11 Titanium

That hasn’t harmed the tactile experience of the ‘unboxing moment’ in any way, shape or form, nor has the gradual increase in recycled materials in the products themselves. For example, the MacBook Air enclosure is 100 per cent recycled aluminium, as is the Mac Studio, with the Air also using 100 per cent recycled rare earth elements in all magnets and 100 per cent recycled copper in the main logic board.

Apple Watch Ultra 3 with 3D-printed titanium case

However, much of this important work is necessarily out of sight and out of mind for the consumer – recycled aluminium looks no different to the virgin material, while rare earth elements are buried deep within the devices. But there are other areas where material innovation, savings and efficiencies can play a major part, as well as help shape design.

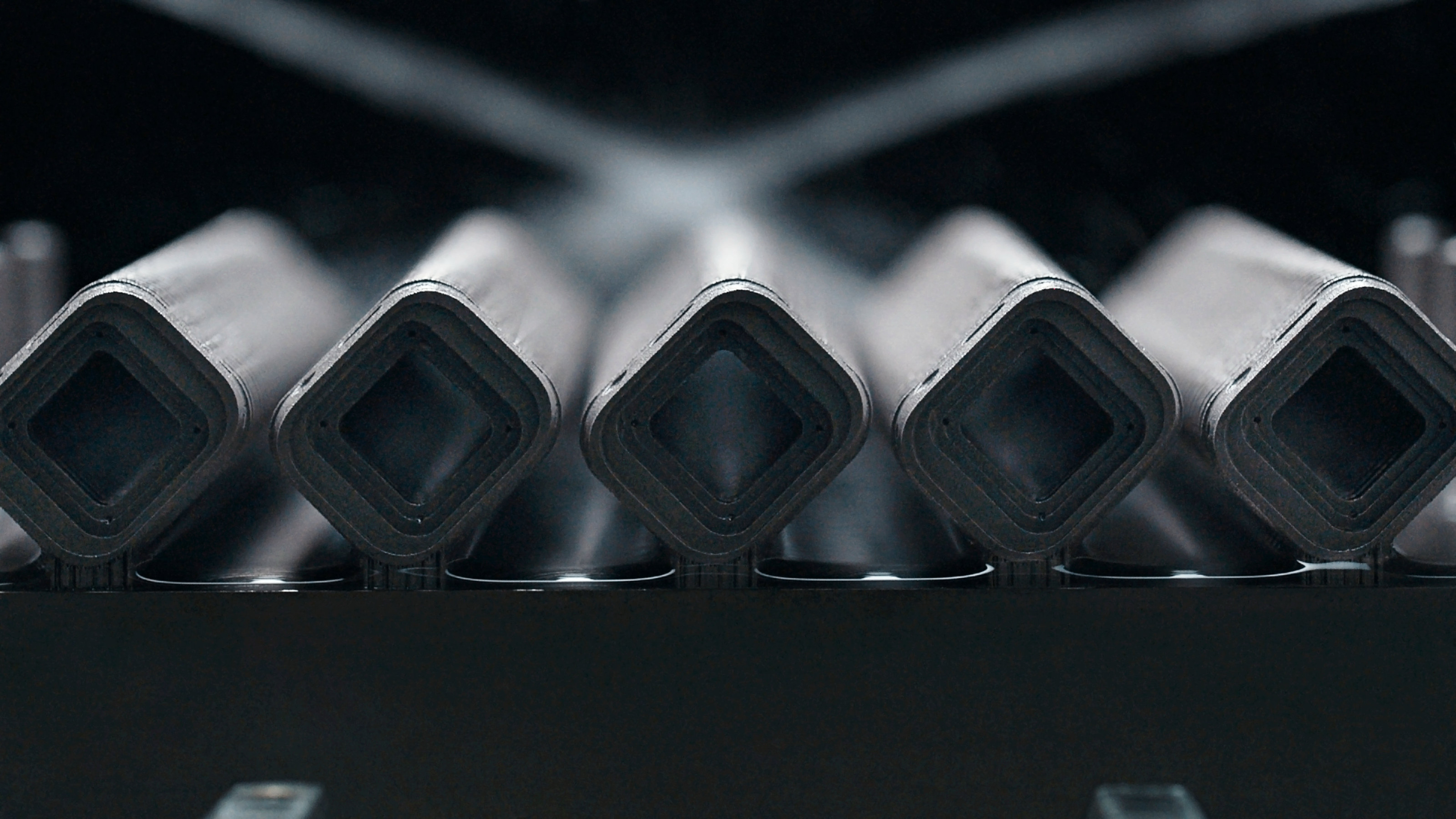

Enter the Apple Watch Ultra 3, the newest flagship Apple wearable with material innovation that’s proudly laid bare. For the first time, the case of the Ultra 3, and that of the titanium Apple Watch Series 11, are made entirely via 3D-printing, using 100 per cent aerospace-grade recycled titanium powder.

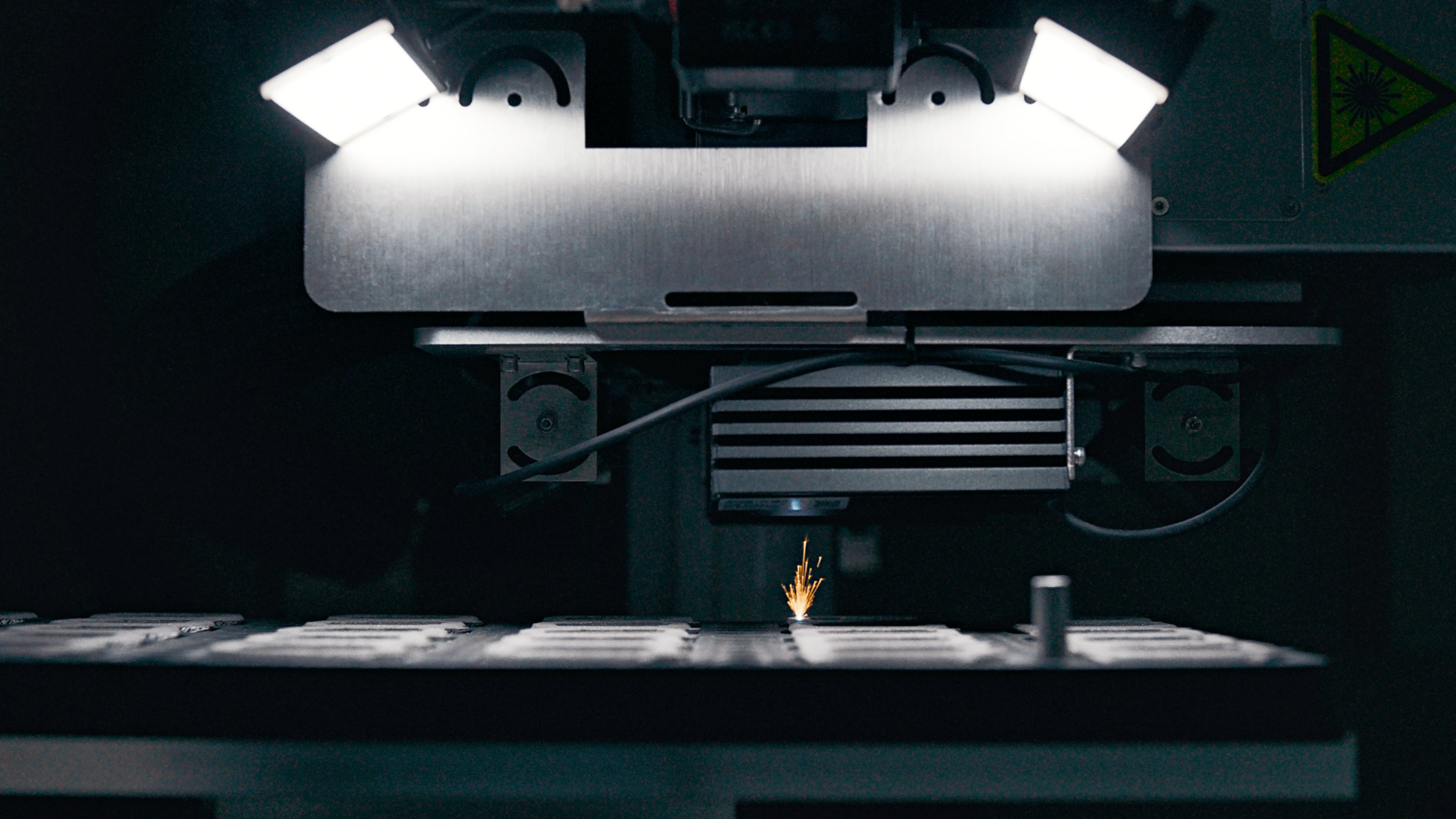

The 3D-printing process – devised and productionised by Apple’s own metallurgy team – uses half the titanium of previous generations of Watch Ultra

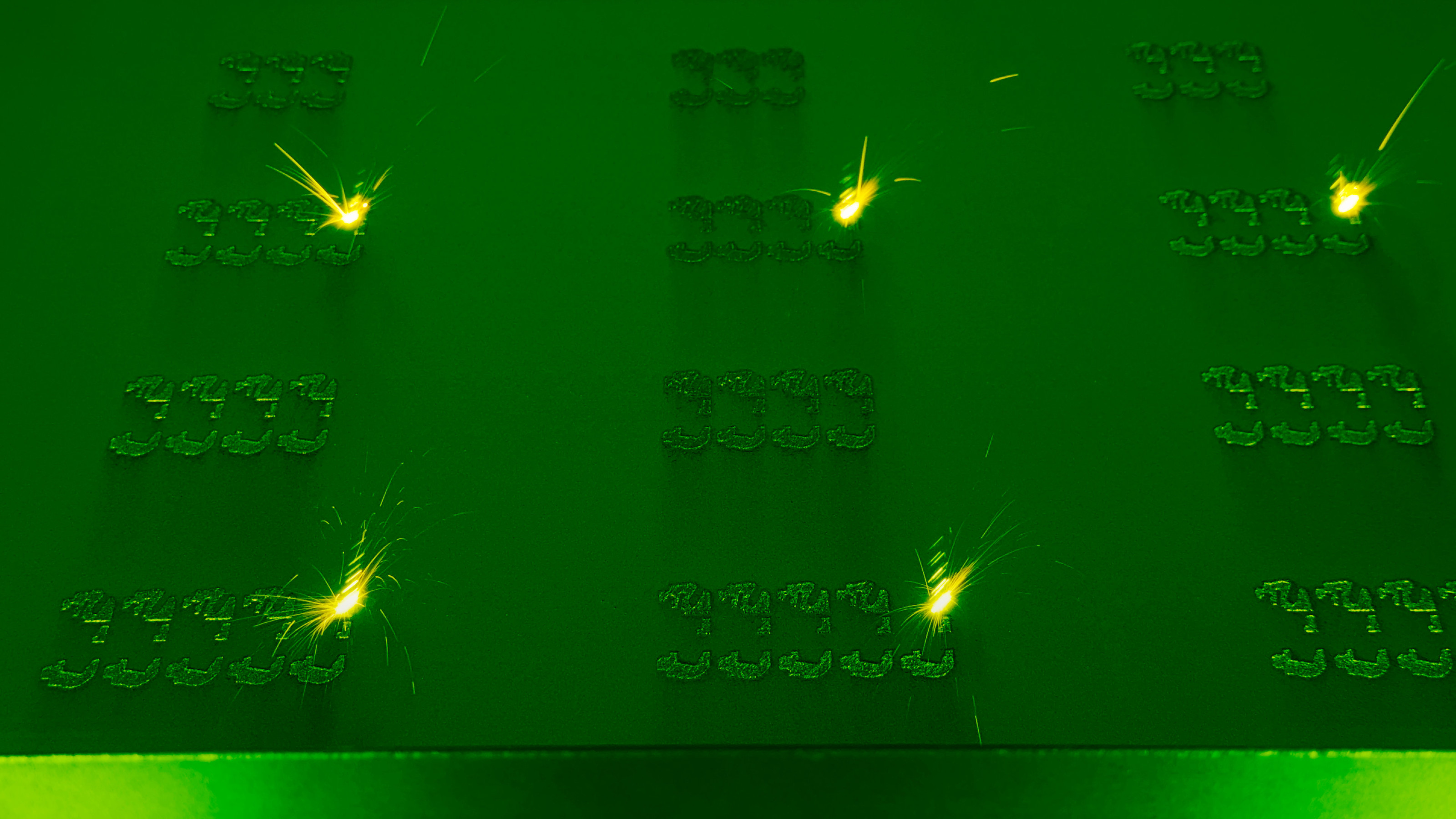

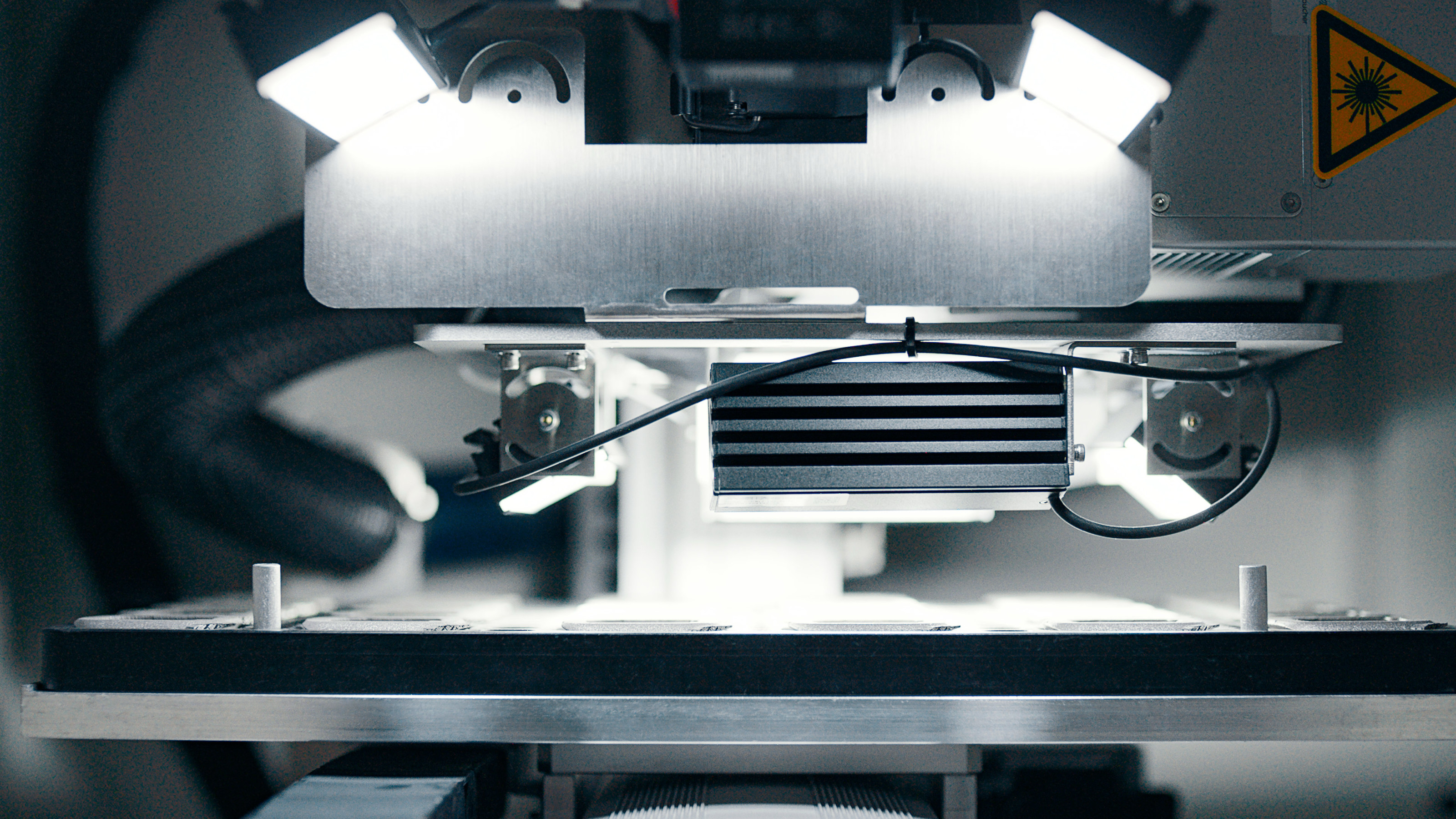

Lasers bake layers of titanium powder into Apple Watch cases

The end result is a spectacular demonstration of how multiple strands of design and research came together to create change. First up, the 3D-printing process – devised and productionised by Apple’s own metallurgy team – uses half the titanium of previous generations of Watch Ultra, where the case was milled from a solid billet of the metal.

Instead, the Ultra 3 uses high-grade powdered recycled titanium, meaning there’s barely any wastage and what remains goes back into the production cycle. On top of this, the energy efficiency of the process has been dramatically reduced.

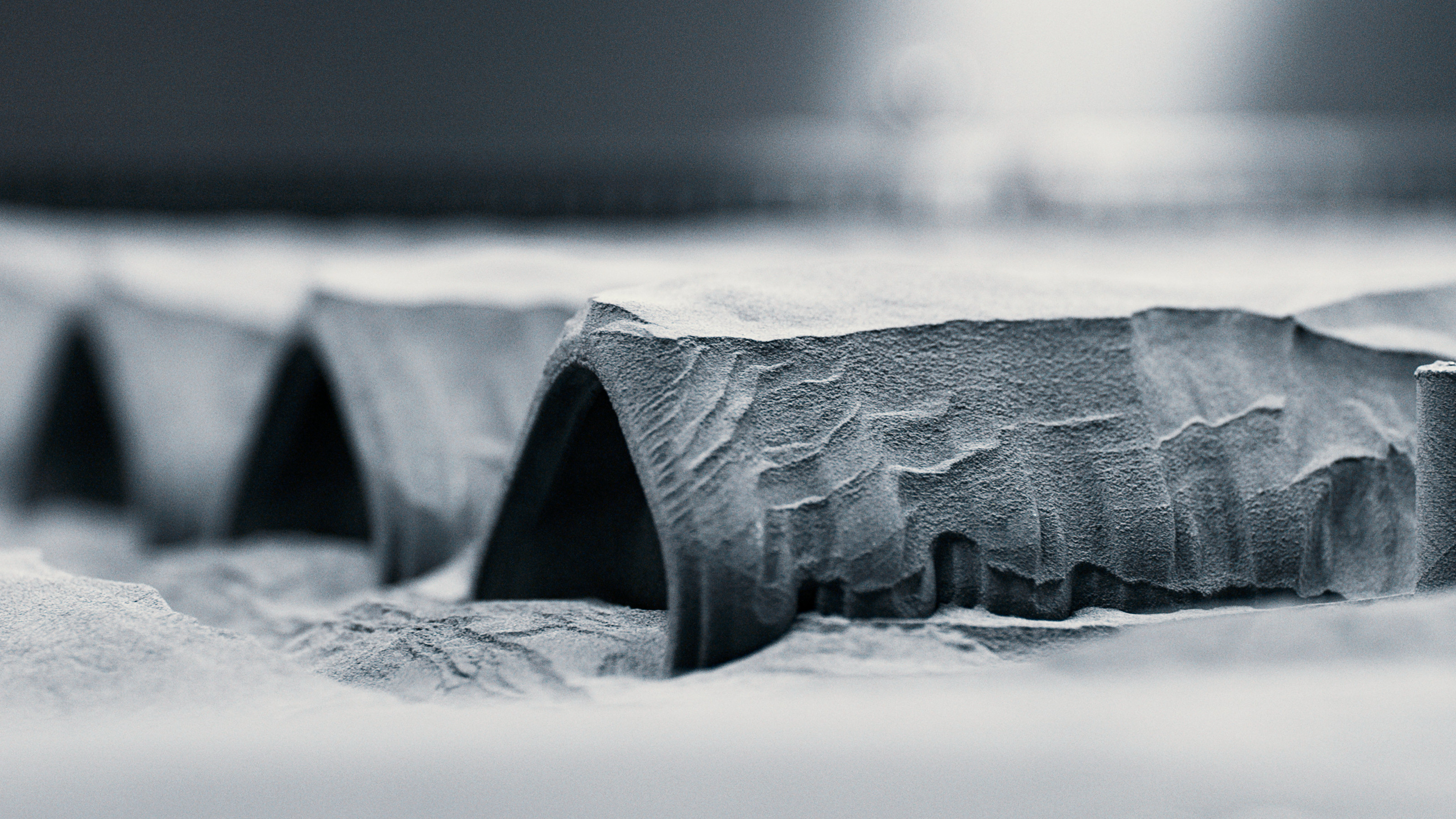

'Rough de-powder: A completed print is raised out of the powder bed, then roughly de-powdered with a vacuum. This vacuumed powder will then be recycled in the 3D printing machine.'

‘Our hope is that [this] can really change the system, change the approach, change how products are made, and help lead the way for others’

Sarah Chandler, vice president of Environment and Supply Chain Innovation at Apple

Focusing on a small element of a very premium product might appear to be a lot of effort for relatively minimal overall benefits. However, according to Sarah Chandler, vice president of Environment and Supply Chain Innovation at Apple, ‘we are now at the point where we are solving the hardest problems – we need to take some really big swings’. What starts with Apple Watch could soon be rolled out into other devices, with correspondingly larger savings.

Receive our daily digest of inspiration, escapism and design stories from around the world direct to your inbox.

'Fine de-powder: This step removes small amounts of remaining powder from facets and small holes. The powder is liberated from the part with pressurised argon and vibration. The powder here is also collected and recycled back into the process.'

But we’re getting ahead of ourselves. ‘We have a long history at Apple of designing with the environment in mind – it's one of our core values,’ says Chandler. Chandler and her team have devoted huge amounts of research and development into realising the new cases, describing the project as a ‘tremendously innovative 3D-printing process’.

‘Our hope is that [this] can really change the system, change the approach, change how products are made, and help lead the way for others,’ Chandler says.

'Part Removal from the build plate: Parts are cut from the build plate using Diamond Wire Sawing, a highly material efficient cutting method.'

Her colleague Kate Bergeron, vice president of Hardware Engineering, describes it as a ‘multi-year journey’. ‘In fact, if we want to go back to the nascent 3D-printing industry, I would say it’s been decades,’ she adds. In essence, the titanium powder is placed on an outline in layers of 60 microns.

A laser solidifies each layer before more powder is added, and the process repeated. ‘We have 900 layers in the UltraWatch, which is just insane,’ says Bergeron, pointing out that ‘we had to invent how we were going to make the parts and invent the material at the same time’.

'Part Marking: The product is laser marked with a 2D barcode for traceability.'

The other challenge is scale. 3D-printed metal is not uncommon, but applications tend to be very high-end and specialised – think aerospace, military, Formula 1 – so to make the process work on ‘Apple scale’ is a big deal. Naturally, this new additive process has resulted in the same levels of surface quality that Apple Watch owners expect, but what they won’t be able to see are the innovations made possible by the new process.

‘Our industrial designers are already thinking about crazy and exciting things they can design that we would never have been able to make before’

Kate Bergeron, vice president of Hardware Engineering at Apple

'Automatic Optical Inspection: The product dimensions are inspected visually with an automated optical inspection system, checking that its dimensions and cosmetics are accurate.'

‘In the Ultra, one thing that we were able to incorporate this time around was additional water sealing,’ says Bergeron. ‘We were also able to make the antenna windows interlock more effectively with the titanium, which we couldn't do using machining. I would say our industrial designers are already thinking about crazy and exciting things they can design that we would never have been able to make before.’

'The near net shape part is now ready to be input to the rest of the manufacturing process in a way similar to a previously forged part. Processes include injection moulding, CNC, polishing and/or sand blasting, lasering, etc.'

This same process is also being deployed under the skin in the iPhone Air, where a new titanium USB-C port enclosure was 3D-printed using the same method, helping achieve its impossible silhouette.

Apple is keen to stress this is systemic change, not just technology for the sake of it. ‘We are trying to find something that can really be an unlock,’ says Chandler. ‘We don't want to just do something once, we want to do it because it becomes the way the whole system works.’

‘We wouldn't develop anything like this as a one-off solution,’ Bergeron clarifies. ‘We look at 3D-printing as a roadmap to the future and so we are absolutely excited to take this technology and apply it in other places where it will make sense. Now that we have this in our toolkit… we can turn it into the next level of innovation.’

Apple Watch Ultra 3, from £749, Apple.com

Apple iPhone Air, from £999, Apple.com

Jonathan Bell has written for Wallpaper* magazine since 1999, covering everything from architecture and transport design to books, tech and graphic design. He is now the magazine’s Transport and Technology Editor. Jonathan has written and edited 15 books, including Concept Car Design, 21st Century House, and The New Modern House. He is also the host of Wallpaper’s first podcast.