How Heath Ceramics sharpened up its act with its first new minimalist cutlery range

The renaissance of California’s Heath Ceramics has become the model reboot of a faltering craft-based design brand. Founded in 1948 by self-taught ceramicist Edith Heath and her husband Brian, the company went into decline when the founders stepped back in 1993. In 2003, designers Catherine Bailey and Robin Petravic chanced upon its dilapidated but still-functioning factory in Sausalito.

The couple bought the company and began its revival. From streamlining its offering and creating new products that built on the Heath design legacy, to opening new showrooms, a new tile factory and keeping production in California, Bailey and Petravic have worked steadily to bring Heath’s founding values and craftsmanship back into the spotlight.

Just in time for its 70th anniversary this year, Heath Ceramics has unveiled its first flatware collection, made together with samples from the production process at the Sherrill factory in New York show the evolution of a spoon; in the first stages of the process, rolled sheet metal blanks are carefully measured to ensure the perfect thickness along each section of flatware; shelves of master tooling for different flatware handles Sherrill Manufacturing, the last remaining flatware maker in the United States and a company with a similar trajectory. Based in Sherrill, New York, the brand was established in 2005 by Gregory Owens and Matthew Roberts, who bought the factory from their former employer, Oneida Limited, after it shuttered following over a century in business.

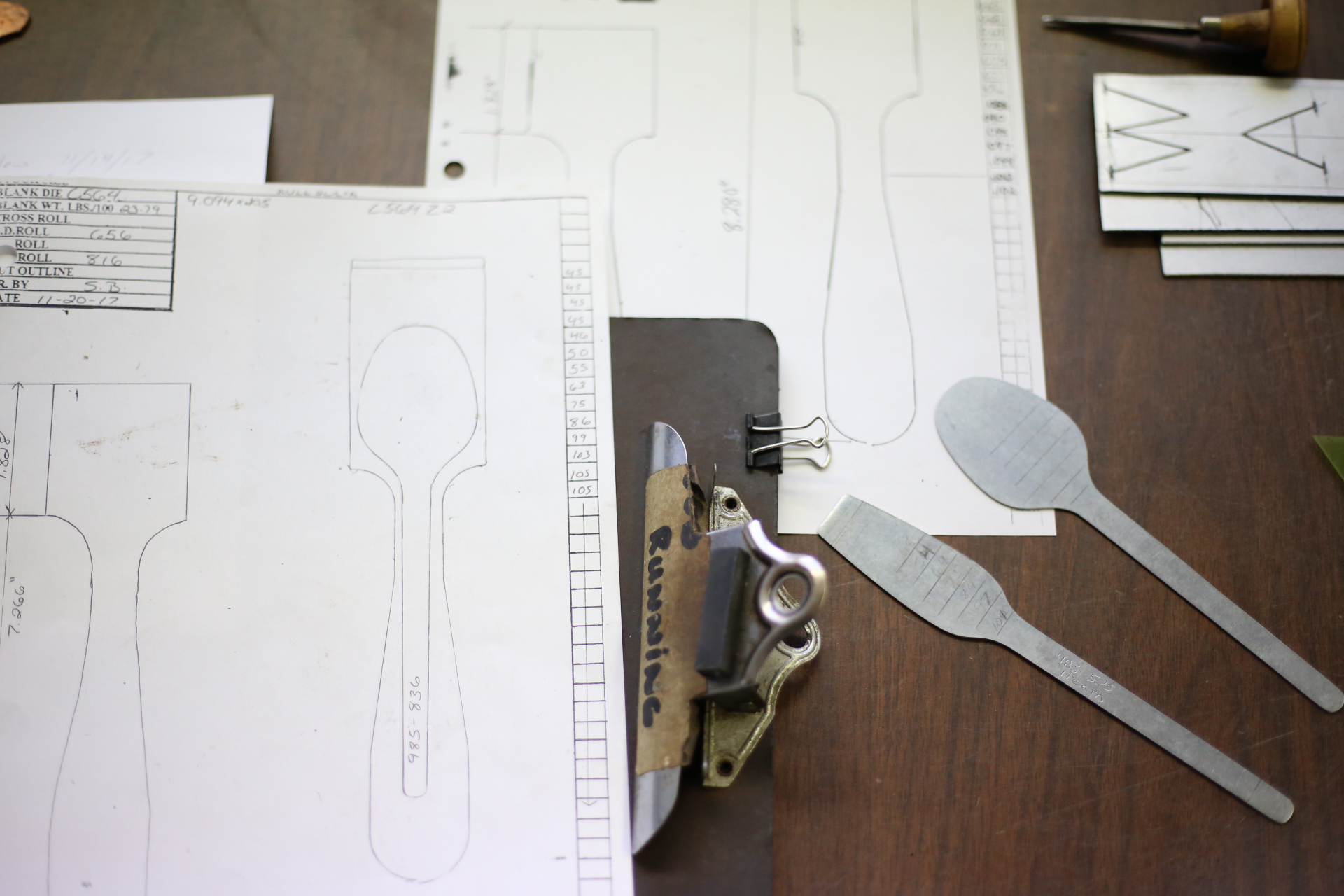

In the first stages of the process, rolled sheet metal blanks are carefully measured to ensure the perfect thickness along each section of flatware

‘Creating our own cutlery has probably been on our wish list for 12 years,’ laughs Petravic. ‘We’ve always been interested in expanding around the dinner plate. We’ve looked for products that express the same ethos of the craftsman-manufacturer-designer and have kept our eyes open for an American manufacturer that we can work with. They are surprisingly hard to find.’

When Petravic and Bailey came across Sherrill and heard its backstory, they saw an obvious fit. In 2014, Heath started to carry a simple cutlery range made by Sherrill in its showrooms. That has now developed into a collection proper, called Muir. ‘We knew they were good people to collaborate with because they were excited to work with us; their other partners weren’t as design driven,’ says Bailey. ‘We wanted the feel of the new flatware to go with our dinnerware, and be both classic and original. They appreciated and respected what we were bringing to the table.’

Samples from the production process at the Sherrill factory in New York show the evolution of a spoon

Designed to complement Edith Heath’s 1948 Coupe ceramics, the Muir cutlery range is an elegant, everyday design that echoes the minimalism of the midcentury and the familiarity of plastic cutlery. It is also the first new flatware collection designed and made in America in almost a decade. With a robust weight to mirror the feel of Heath’s dinnerware, the five pieces – a dinner knife, dinner fork, soup spoon, teaspoon and salad fork – have been individually made from American stainless steel.

‘The Muir profile looks a little top-heavy, there is a child-like playfulness to the proportion,’ explains Tung Chiang, Heath Ceramics’ creative lead and studio director. ‘I was actually inspired by a plastic ice cream spoon. Heath is about designing something that can be used every day. I wanted it to feel casual. There is a slow, gradual transition towards the utensil’s flat handle, which creates an arc so that you can easily grab it. There is also a kick at the back of the handle so that the pieces lift off the table.’

Shelves of master tooling for different flatware handles

Despite producing quality pieces in big volumes, Sherrill still uses methods dating back to the 1950s. Instead of digital files and three-dimensional CAD drawings, the company works with hand-drawn sketches. Similarly, there are no automated, computer-controlled machines; instead, tooling is worked by hand. It often takes around 15 to 20 different processes of moulding, stamping and die-cutting to create each utensil. From rolling each spoon out to ensure a perfect balance between bowl and handle, to refining the spacing between the forks’ tines and forging each knife out of a rod of steel, producing each utensil required a continual dialogue between designer and manufacturer.

‘Current technology allows us designers to entertain the notion that our vision will be executed in a certain way,’ explains Chiang. ‘To trust a manufacturer like Sherrill, learn from them and respect their past was really exciting. You feel like you are preserving their history and an old technology that still works.’

The collection’s final flourishes come in the form of a handwritten logo carved onto the back of each piece, and packaging designed by House Industries. With two more collections to come (riffs on the traditional Colonial and Teardrop flatware patterns), Heath Ceramics continues to celebrate hard-earned utilitarian minimalism. ‘We want to create objects that just disappear around you and become part of your life and environment,’ Chiang insists.§

As originally featured in the July 2018 issue of Wallpaper* (W*232)

Metal rods are placed into a large furnace before being flattened into knives

A craftsman grinds down the forming tool that creates the bowl of a spoon

INFORMATION

Muir range, $72 for set of five, available from 17 July, by Heath Ceramics. For more information, visit the Heath Ceramics website

Receive our daily digest of inspiration, escapism and design stories from around the world direct to your inbox.

Pei-Ru Keh is a former US Editor at Wallpaper*. Born and raised in Singapore, she has been a New Yorker since 2013. Pei-Ru held various titles at Wallpaper* between 2007 and 2023. She reports on design, tech, art, architecture, fashion, beauty and lifestyle happenings in the United States, both in print and digitally. Pei-Ru took a key role in championing diversity and representation within Wallpaper's content pillars, actively seeking out stories that reflect a wide range of perspectives. She lives in Brooklyn with her husband and two children, and is currently learning how to drive.