Double act: the making of Handmade 2015's picnic whisky set, by Peter Ivy

Receive our daily digest of inspiration, escapism and design stories from around the world direct to your inbox.

You are now subscribed

Your newsletter sign-up was successful

Want to add more newsletters?

Daily (Mon-Sun)

Daily Digest

Sign up for global news and reviews, a Wallpaper* take on architecture, design, art & culture, fashion & beauty, travel, tech, watches & jewellery and more.

Monthly, coming soon

The Rundown

A design-minded take on the world of style from Wallpaper* fashion features editor Jack Moss, from global runway shows to insider news and emerging trends.

Monthly, coming soon

The Design File

A closer look at the people and places shaping design, from inspiring interiors to exceptional products, in an expert edit by Wallpaper* global design director Hugo Macdonald.

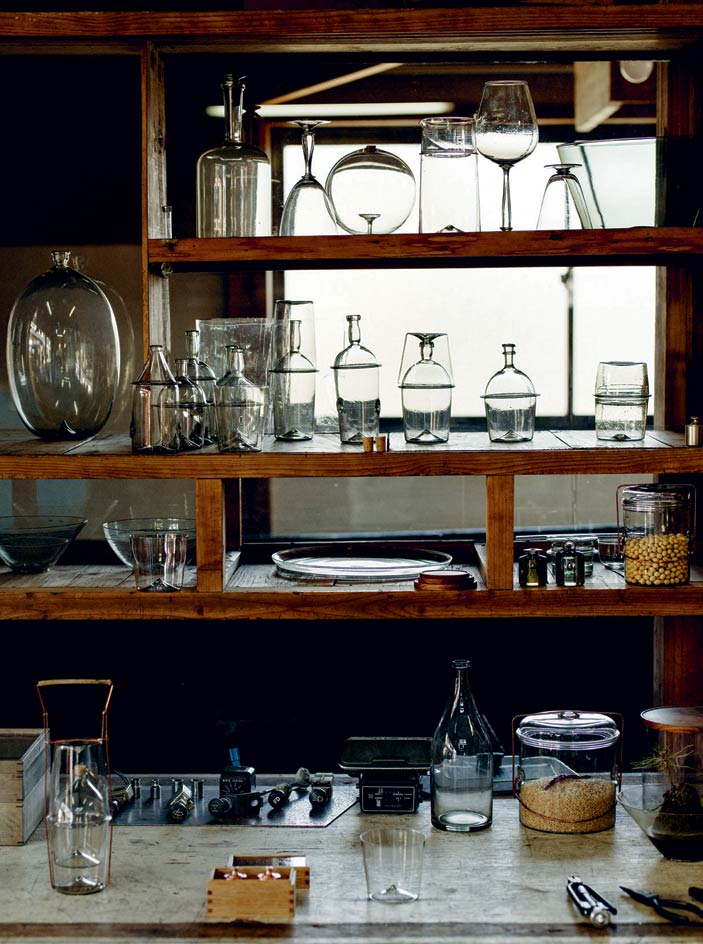

It would be hard to think of anyone more appropriate for making our bespoke whisky set than Peter Ivy. His reasons for doing what he does are exactly what Wallpaper* Handmade is all about. Originally from Austin, Texas, he now works from his small studio in a tiny hamlet just outside of Toyama, Japan, where he pursues a collaborative, hands-on effort, working with an assistant, always striving for a result slightly better than before. That he loves one-off projects, as opposed to making the same thing over and over again, made this an even better fit.

Ivy studied product design at the Rhode Island School of Design, but he quickly discovered that he didn’t like the way manufacturing was heading, with design and production being split into two completely different entities, often across large distances both culturally and physically. He wanted to be closer to the actual creation process and by chance stumbled upon glass making during his student days. He was hooked. ‘I like the mental focus and physical coordination needed,’ he explains. ‘Glass is fluent, and contrary to what many people think, you cannot really control it, but rather only make suggestions with your hands and tools towards the shape you are striving for.’ It seems he must be very good at making suggestions. This becomes clear if you look at the level of precision exhibited in all his pieces – for example, the perfect fit of the cups and bottles for the Wallpaper* Handmade whisky set, or the lids for his coffee bean and rice jars.

Ivy had a clear idea of what he wanted to do from the very beginning. ‘I had done a shochu picnic set before,’ he says, referring to the Japanese spirit, ‘and had wanted to work on a version for whisky for a long time. This was the perfect excuse to do so.’ Our initial idea was to have him make a bottle and glass set and use granite ‘ice cubes’ to cool the dram. However, through his research, Ivy learned that such stones weren’t the best solution for anyone serious about whisky. Instead, he came up with the idea of using custom-made copper ‘weights’ to cool the drink. ‘When considering which materials to use, I thought of the process of how whisky is made,’ he explains. The copper stills used during distillation led him to the idea. Copper has the added benefit of being an excellent thermal conductor and matches perfectly with the copper-coated steel wire mechanism Ivy settled upon to hold the bottle and glass, or glasses, together.

Rather than theorise a design, Ivy likes to get right down to it and work on the idea to find the perfect shape. ‘It’s the doing and thinking that distils the idea.’ Pun unintended, he explains with a smile. Once he had decided on the general form, it was just a matter of perfecting each element.

Ivy worked on two versions, a one-glass and a two-glass set. In the first, the glass sits snugly over the top of the whisky bottle, while in the second, the bottle appears to float mid-air between two glasses by way of a small fold in the middle of the bottle, which rests on the edge of the bottom glass. These pieces are all made from recycled glass reclaimed from fluorescent tubes. Ivy likes this low-grade, hard-to-use material, because of the textural quality that the many small imperfections (bobbles, unevenness) give to his final product. He made grooves in the bases of each glass to accommodate the simple, almost flimsy, wire mechanism with a small bamboo handle that holds them together with the bottle.

To cool the whisky, Ivy had a friend mill two copper weights, which are presented in a small carrying box made of Japanese oak (again, a reference to whisky making). The weights should be chilled in advance and lowered into each glass to cool the whisky – fitting snugly on the vessels’ kick-up bases (or ‘kicks’ as Ivy calls them) – then removed before drinking.

Ivy likes to have several layers to his work. There is the overall aesthetic, but when you look more closely you notice small details that add depth and interest. Irregularities in the glass decorate the seemingly plain surface. Jack marks (lines left from the tool used to ‘open’ the glass) circumvent the top 2cm or so of the glass and are deliberately not smoothed out, remaining as clues as to how the set was made. It has been said that it is the little inaccuracies that characterise quality handcraftsmanship. We’ll drink to that.

As originally featured in the August 2015 edition of Wallpaper* (W*197)

As a student, Ivy quickly discovered that he didn’t like the way manufacturing was heading, with design and production being split into two completely different entities; he wanted to be closer to the actual creation process and by chance stumbled upon glass making

‘Glass is fluent, and contrary to what many people think, you cannot really control it, but rather only make suggestions with your hands and tools towards the shape you are striving for,’ he says

‘I had done a shochu picnic set before,’ he says, referring to the Japanese spirit, ‘and had wanted to work on a version for whisky for a long time. This was the perfect excuse to do so’

Rather than theorise a design, Ivy likes to get right down to it and work on the idea to find the perfect shape. ‘It’s the doing and thinking that distils the idea.’ Once he had decided on the general form, it was just a matter of perfecting each element

Ivy worked on two versions, a one-glass and a two-glass set. The pieces are all made from recycled glass reclaimed from fluorescent tubes

Receive our daily digest of inspiration, escapism and design stories from around the world direct to your inbox.

Originally from Denmark, Jens H. Jensen has been calling Japan his home for almost two decades. Since 2014 he has worked with Wallpaper* as the Japan Editor. His main interests are architecture, crafts and design. Besides writing and editing, he consults numerous business in Japan and beyond and designs and build retail, residential and moving (read: vans) interiors.