Discover the watch bracelets of the future at Watches and Wonders 2024

A new space at Watches and Wonders 2024, the LAB, turns its gaze to the future of watchmaking

Receive our daily digest of inspiration, escapism and design stories from around the world direct to your inbox.

You are now subscribed

Your newsletter sign-up was successful

Want to add more newsletters?

Daily (Mon-Sun)

Daily Digest

Sign up for global news and reviews, a Wallpaper* take on architecture, design, art & culture, fashion & beauty, travel, tech, watches & jewellery and more.

Monthly, coming soon

The Rundown

A design-minded take on the world of style from Wallpaper* fashion features editor Jack Moss, from global runway shows to insider news and emerging trends.

Monthly, coming soon

The Design File

A closer look at the people and places shaping design, from inspiring interiors to exceptional products, in an expert edit by Wallpaper* global design director Hugo Macdonald.

As this year’s Watches and Wonders is in full swing, with visitors descending from over 125 countries to discover all that is brand new in the watch world, our gaze is fixed further ahead. An intriguing new space at this year’s show, the LAB, is to be found at the heart of Geneva’s Palexpo, asking the question – what is tomorrow’s watchmaking going to look like?

A team of engineers, start-ups and schools are celebrating innovation and new technologies, offering an immersive and temptingly tactile experience to all. Particularly intriguing is the ‘ECAL’ area (The École Cantonale d'Art de Lausanne), where 15 students will present their designs for the watch bracelets of the future. Here, we speak to Nicolas Le Moigne, head of MAS in Design for Luxury & Craftsmanship at ECAL, about what we can soon expect to be sporting.

The watch bracelets of the future

Seunghyeon Yoo

Wallpaper* Can you tell us a bit about the watch straps designs we can expect to see here?

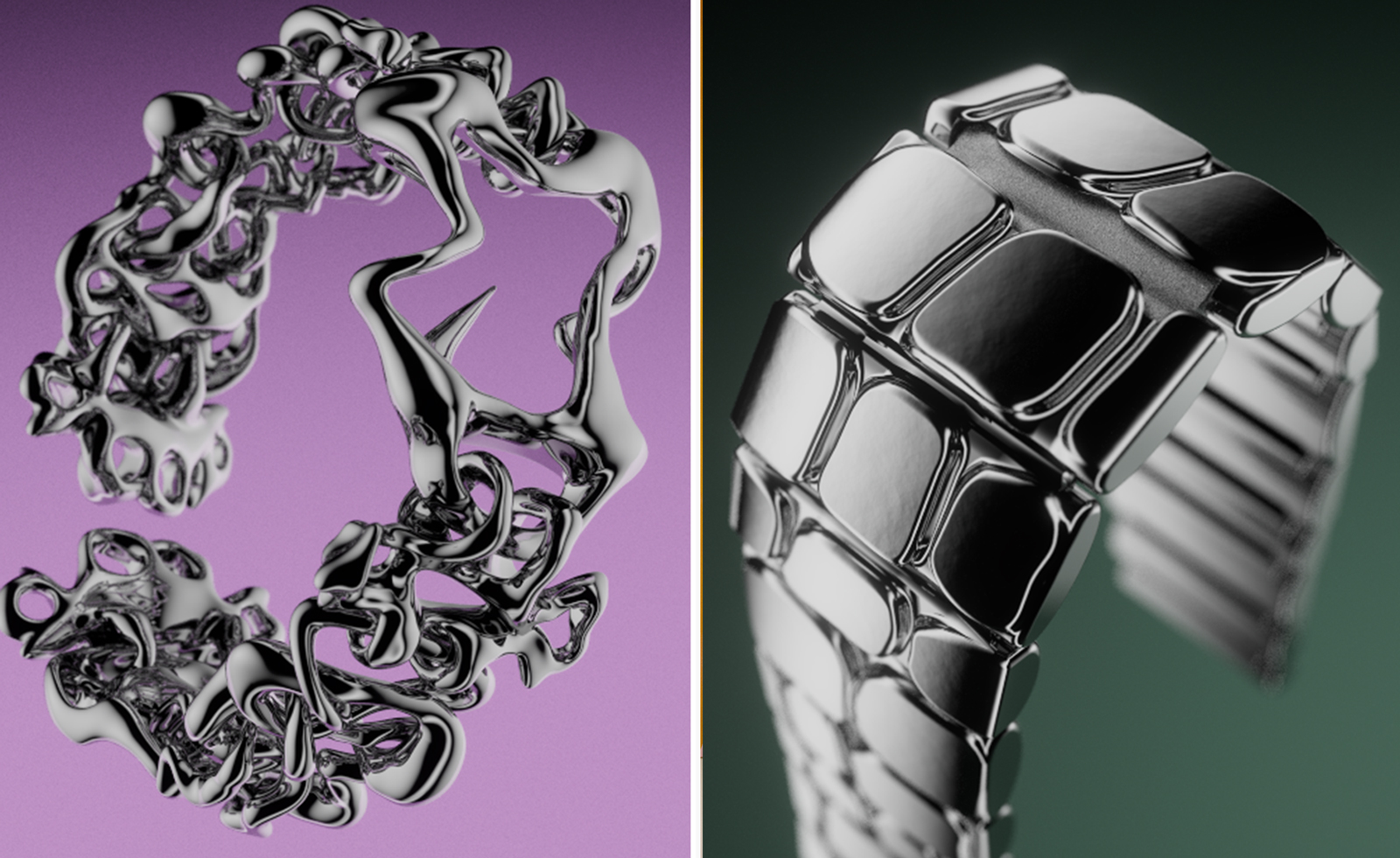

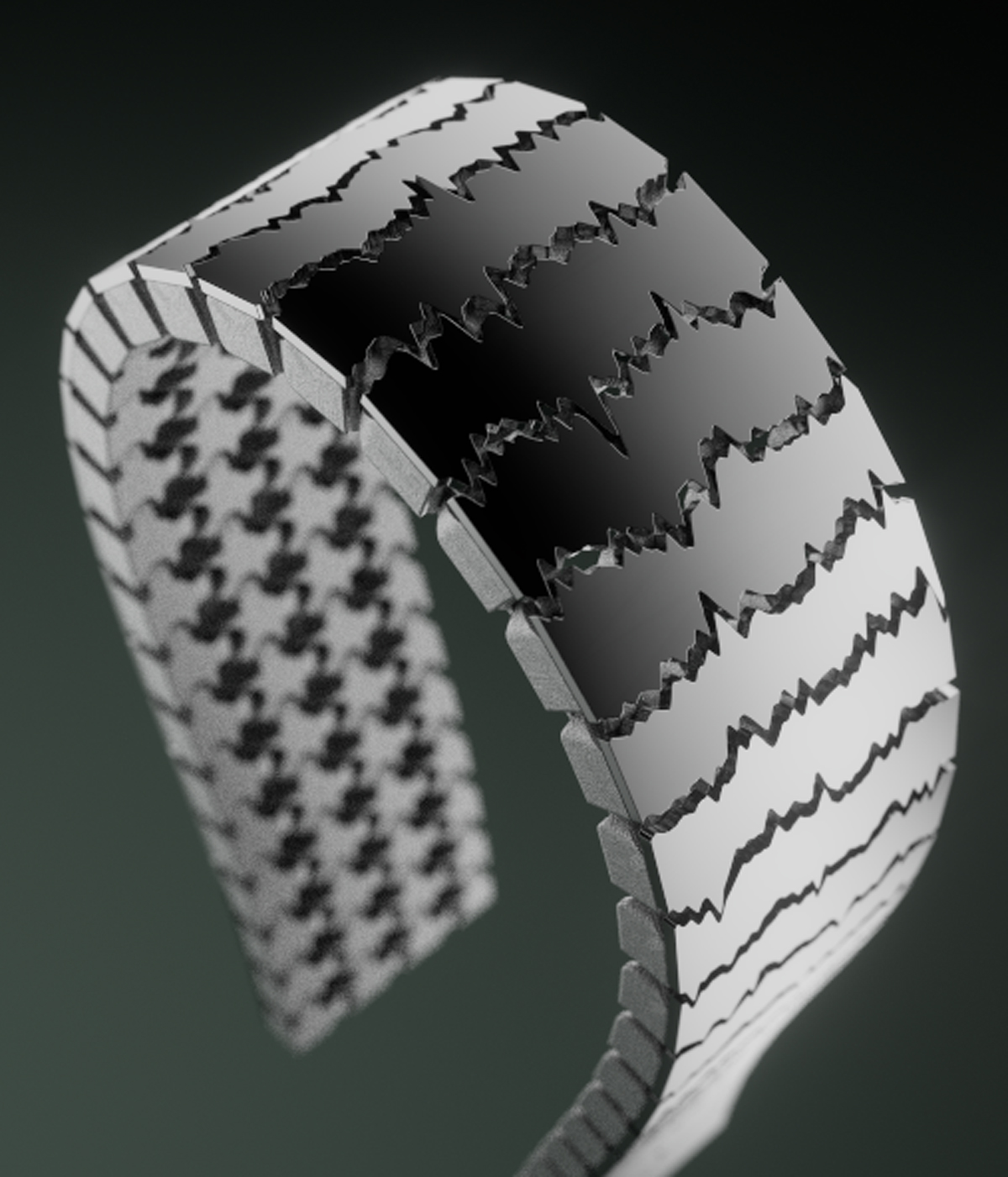

Nicolas Le Moigne: For the Watches and Wonders Geneva 2024 trade show, ECAL/University of Art and Design Lausanne has teamed up with Alloyed, a company that specialises in metal printing technologies, to present an original collection of watch straps. Designed by students in the Master of Advanced Studies in Design for Luxury and Craftsmanship programme, these wristbands have been developed using 3D modelling software, resulting in unique pieces that go beyond the limits of traditional techniques.

Five of the 15 concepts designed by the students were selected and 3D printed from a fine powder of TI6AI4V titanium—an alloy composed of titanium, aluminium, and vanadium—whose melting point of around 1,600° Celsius is obtained using a laser beam. Regularly used in the aerospace, and medical industries, this printing technique, known as Laser Powder Bed Fusion (L-PBF), can be used to create objects with ultra-high-performance mechanical properties.

Each project, presented in the form of a prototype or animation, finds its inspiration in the beauty of nature, through organic structures, as much as in complex systems, closer to engineering. This collaboration brings together technology, craftsmanship, and design—with links to the world of fine watchmaking—by combining the expertise of engineers specialising in the science of materials, the know-how of artisan jewellers and their finishing skills, and the creativity and innovative spirit of up-and-coming designers.

W: What is the biggest change you can foresee in watch strap designs of the future?

Receive our daily digest of inspiration, escapism and design stories from around the world direct to your inbox.

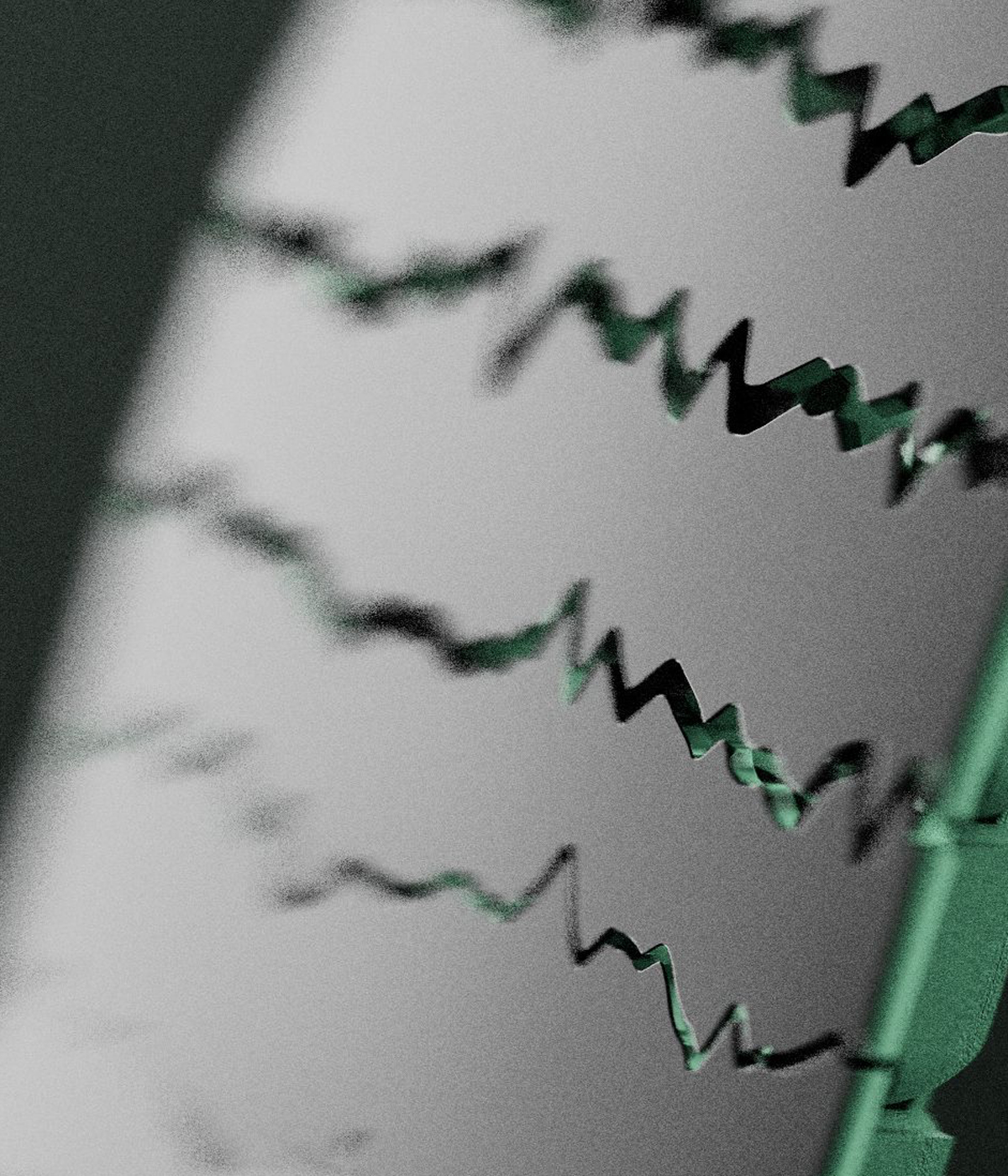

NLM: With the L-PBF process, complex geometries can be realised close to the net-shape design, enabling complex features such as hollow organic structures to be realised and articulating links to be directly printed “assembled”.

Seunghyeon Yoo

W: What advances in materials can we look forward to?

NLM: The titanium alloy offers a compelling combination of properties with excellent bio-compatibility and corrosion resistance with a high strength-to-weight ratio that provides durability and makes objects highly wearable. In its natural state, the alloy offers a unique grey hue, with the possibility to also develop a wide-ranging colour palette through surface modification by anodization, temperature alterations or coating technologies.

Besides the design freedom unlocked, the LB-PBF process represents a sustainable approach with efficient use of raw input powder material and less wastage found in typical CNC machining or casting approaches.

W: How are people’s expectations of their watch straps changing?

NLM: The development and possibilities offered today by metal 3D printing technologies, previously used only in the development process for a bracelet or a watch case, now makes it possible to produce parts that are an integral part of the finished product. Thanks to 3D modelling softwares, it would be then possible to offer customers the chance to go even further in personalising their watch.

Watches and Wonders 2024 runs from 9 April - 15 April 2024

Hannah Silver is a writer and editor with over 20 years of experience in journalism, spanning national newspapers and independent magazines. Currently Art, Culture, Watches & Jewellery Editor of Wallpaper*, she has overseen offbeat art trends and conducted in-depth profiles for print and digital, as well as writing and commissioning extensively across the worlds of culture and luxury since joining in 2019.