Inside Brompton: a pioneering provider of folding bicycles for fifty years

Below the fold, we explore the history and ethos of Brompton Bicycles and take a tour of the bike maker’s London factory as it comes up on its half century

Brompton is fifty years old. The British bike manufacturer – and pioneer in folding bike technology – is not only a major exporter, but also one of the few major manufacturing concerns to remain in London. Wallpaper* visited the factory in Greenford, north-west London, to find out more about this cult object and staple of city mobility. The company has grown substantially since it re-located here in 2011, and other operations spill out into other buildings.

The factory is the kind of identikit shed that could be anything from a DIY store to a distribution centre, but inside there’s a steady thrum of noise and activity. Brompton usually makes around 2,000 bicycles a week (it was up to 2,700 at the peak of production during Covid). A huge number of components are made in house, including wheels, frames and folding mechanisms. Some parts are shipped in, with suppliers sourced in China (hubs, rims and brakes), cables (Belgium) and mudguards (France).

An original Bickerton, an example of a pre-Brompton folding bike

Here you’ll find teams putting together the newer, larger electrified Brompton G Line and the ultra-light titanium-framed T Line, as well as the classic original C Line, the ultra-compact A Line and the performance focused P Line.

When Andrew Ritchie founded Brompton in 1975 – in a flat overlooking the Brompton Oratory in South Kensington – his primary innovation was the folding mechanism. Quick, secure and compact, it ultimately turned the bicycle into a commuter’s dream, capable of being stashed in a cupboard, under a desk or in a train compartment, or simply ridden through the city streets.

A collection of Bromptons, old and new, at the company's London factory

Like all good origin stories, Ritchie had a fair number of hurdles to clear, starting with many prototypes and iterations, followed by rejection from some of the (then) big names in British cycle manufacturing. It wasn’t until 1987 and a substantial investment from Julian Vereker, the founder of Naim Audio, that it all came together and Brompton started winning plaudits and export orders. The original factory – two railway arches in Brentford – was no longer enough for a company fast becoming an icon of British design and manufacturing in markets like Japan.

The Brompton frame in all its glory

That folding mechanism is still in use today, along with the brazing method of joining the metal, as opposed to conventional welding. Unlike welding, brazing uses another type of metal to fuse two pieces together – in this case a brass alloy. This creates a much more durable joint with better toleration for the folding mechanism. The titanium framed bikes are put together at specialist firm in Sheffield, while the steel tubes and pressings also come from external suppliers.

Brompton

Out of this forest of parts, a bicycle emerges, with all the individual partwork processes that go into making up the frame, the wheels, etc., all coming together at a workstation where individual team members put together a completed bike in a series of stages. It takes about a week for a frame to be made and 4-6 weeks to fulfil an order, but once all the components are ready and waiting to be assembled, the process takes around half an hour for each bike. Only the electrified G Line, with its more complex assembly, takes longer.

Receive our daily digest of inspiration, escapism and design stories from around the world direct to your inbox.

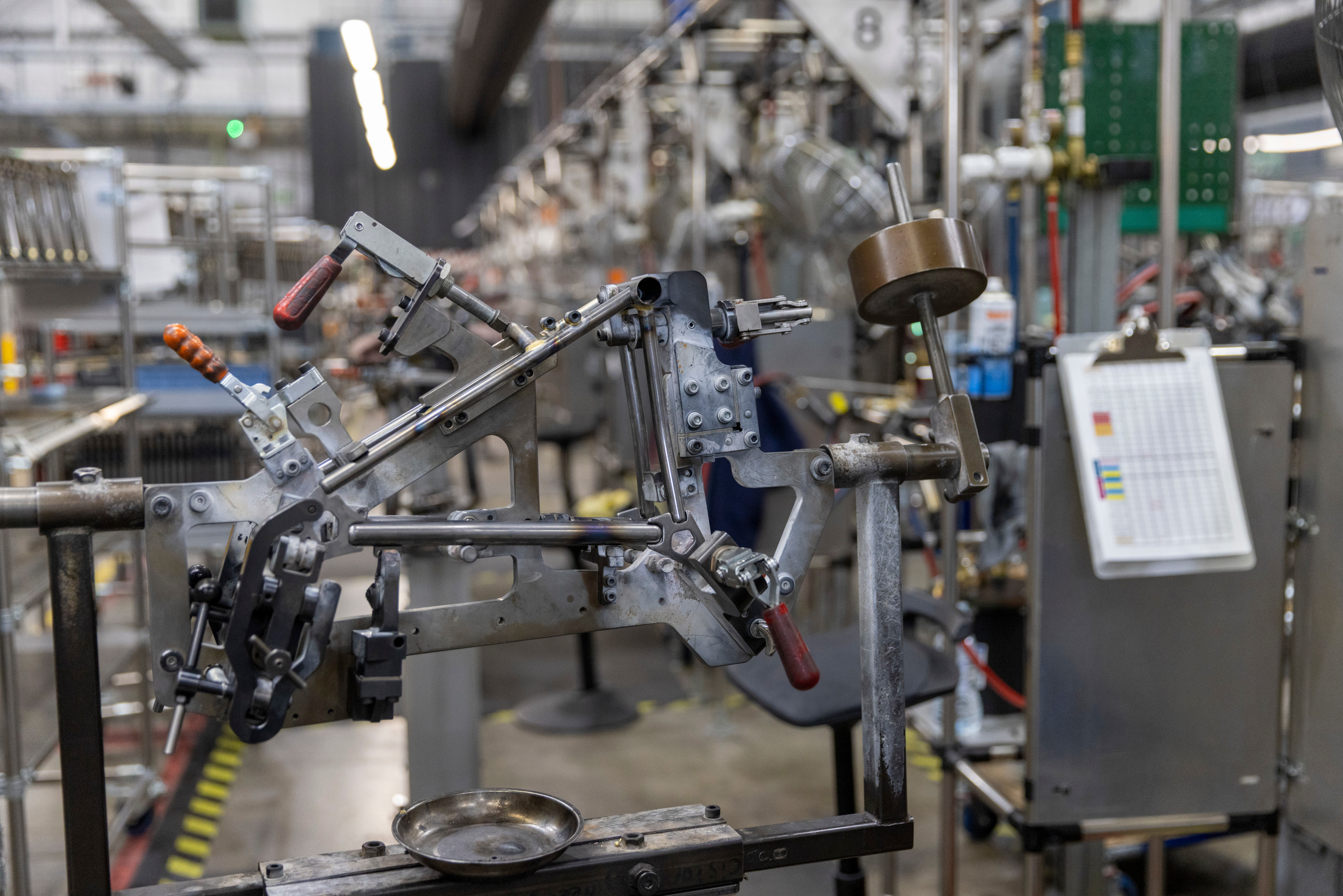

Components for the forks are assembled on jigs before brazing

One of the major developments in modern Brompton manufacturing is the focus on the hinge, a crucial joint that is placed under a great of street in daily riding. Originally the joins had to hand-brazed, but now a specially designed machine precisely controls the process. There’s a rich mix of old and new, from 40-year-old presses to modern polishing robots.

A modern paint shop powder coats all the parts, then bakes on the powder in a uniform manner. Bikes are painted in batches according to colour, with a vast vertical ‘filing cabinet’ storing up to 4,000 individual parts (a week’s worth of production), ready for assembling.

Completed forks await painting and assembly

One other great advantage of a folding bike is the space taken up for shipping. Bromptons are dispatched in compact boxes that are a world away from the vast slabs of cardboard packaging required to transport regular bikes around the world.

Brompton bicycles ready for shipping

While special orders and custom requests are common, Brompton has also delved deep into the possibilities offered up by creative collaboration. Of three production lines, Line 1 is dedicated to these specials. In recent years, these have included fashion forward collaborations with Anya Hindmarsh, Palace, Freitag, and Oliver Spencer, amongst others.

Colour choice: folded Bromptons on show at the factory

Down the road from the main factory is Brompton’s R&D department, filled with rattling and hissing equipment running durability tests on prototypes and new innovations. The company is in the midst of an ongoing design renaissance, exploring and re-evaluating every facet of the form, material and mission of its bikes. The switch to titanium for the flagship T Line is a case in point; the ultra-light metal does away with the Achilles Heel of the original Brompton, namely its heft.

Wheels being balanced

Durability is also essential. As Brett Boone, Brompton’s Head of Reliability, notes, a traditional bike frame is fundamentally structurally sound thanks to its triangular form. Not so with a Brompton. Every aspect of urban life, from potholes to puddles, load lugging, inclines and unexpected dings and dents, are simulated and thrown at the frames. Failures are induced in order to design them out (‘failure is just insight’, says Boone) and every component that has to fold, like the hinge and the cables, is tested to destruction.

Brompton's paint shop

The output from Brompton's paint shop

The overall goal is to find the balance between durability and lightness. Cost is also a consideration, of course. A single-speed T Line starts at £4,250, compared to £1,449 for the original six-speed C Line. The latter weighs in at 12kg, while the T Line is just 7.45kg. Enthusiasts will naturally pay more for the performance advantage.

An overall view of the Brompton factory in Greenford

Brompton’s Chief Design and Engineering Office is Will Carleysmith. A youthful veteran with 22 years at the company, seeing it grow from around 60 people to nearly 800. Although design – and collaboration – remain an integral part of the Brompton image, Carleysmith is under no illusion that this is an ‘engineered product.’ Everything that comes out of the factory is shaped by innovation, not marketing.

The brazing process underway

Carleysmith recalls that when joined the company, there was a single steel bike on offer, ‘a handmade, legacy product.’ The then factory worked on a principle of one person per bike, with no automation. Many components simply didn’t exist and had to be built in-house from scratch. As Brompton has evolved, so have suppliers. ‘We’ve had the fundamental advantage of staying relevant for so long that a lot of our suppliers have to pivot (to us),’ Carleysmith says, ‘we were urban mobility long before people started having urban mobility conferences.’

Final assembly at the Brompton factory

Brompton remains an outlier. Around the world, some 40 million bikes are made each year and only a tiny fraction of these are folding. ‘We’re out there on our own,’ says Carleysmith, ‘so we tend to be deeper in our acquisition of data [than our rivals]. That informed our choice of titanium – light and strong. A Brompton doesn’t have to be treated with respect – it’s absolutely bullet proof.’

Finished wheels awaiting installation

The team is drawn from a number of different places, including automotive, military and even aerospace. ‘We bring in very good people from very disparate industries,’ says Carleysmith, ‘we’re a synthesis of disciplines.’

There’ll doubtless be something along soon to celebrate the company’s half-century. Carleysmith acknowledges that although ‘London is a Brompton city – most people here know about us’ – that recognition isn’t as high as they’d like elsewhere. Brand partnerships help spread the message – ‘they’re an opportunity to explain why the product is what it is,’ he adds. ‘Perhaps we’re not a particularly intuitive brand to understand… At the end of the day, we’re a funny little bicycle with little wheels.’

Brompton Tour de France edition

Brompton clearly sees a role for itself in a future where urban mobility comes under more and more scrutiny. Carleysmith himself rides an electric G Line. ‘I can really fly around the city,’ he says, ‘that’s the joy of developing bicycles – you really get to experience them.’

Jonathan Bell has written for Wallpaper* magazine since 1999, covering everything from architecture and transport design to books, tech and graphic design. He is now the magazine’s Transport and Technology Editor. Jonathan has written and edited 15 books, including Concept Car Design, 21st Century House, and The New Modern House. He is also the host of Wallpaper’s first podcast.