We delve behind the design of Citroën’s eccentric ELO concept car

The Citroën ELO brings sportswear-infused materials into a multifunctional automotive interior. The concept car’s design team talk us through the project

Receive our daily digest of inspiration, escapism and design stories from around the world direct to your inbox.

You are now subscribed

Your newsletter sign-up was successful

Want to add more newsletters?

Daily (Mon-Sun)

Daily Digest

Sign up for global news and reviews, a Wallpaper* take on architecture, design, art & culture, fashion & beauty, travel, tech, watches & jewellery and more.

Monthly, coming soon

The Rundown

A design-minded take on the world of style from Wallpaper* fashion features editor Jack Moss, from global runway shows to insider news and emerging trends.

Monthly, coming soon

The Design File

A closer look at the people and places shaping design, from inspiring interiors to exceptional products, in an expert edit by Wallpaper* global design director Hugo Macdonald.

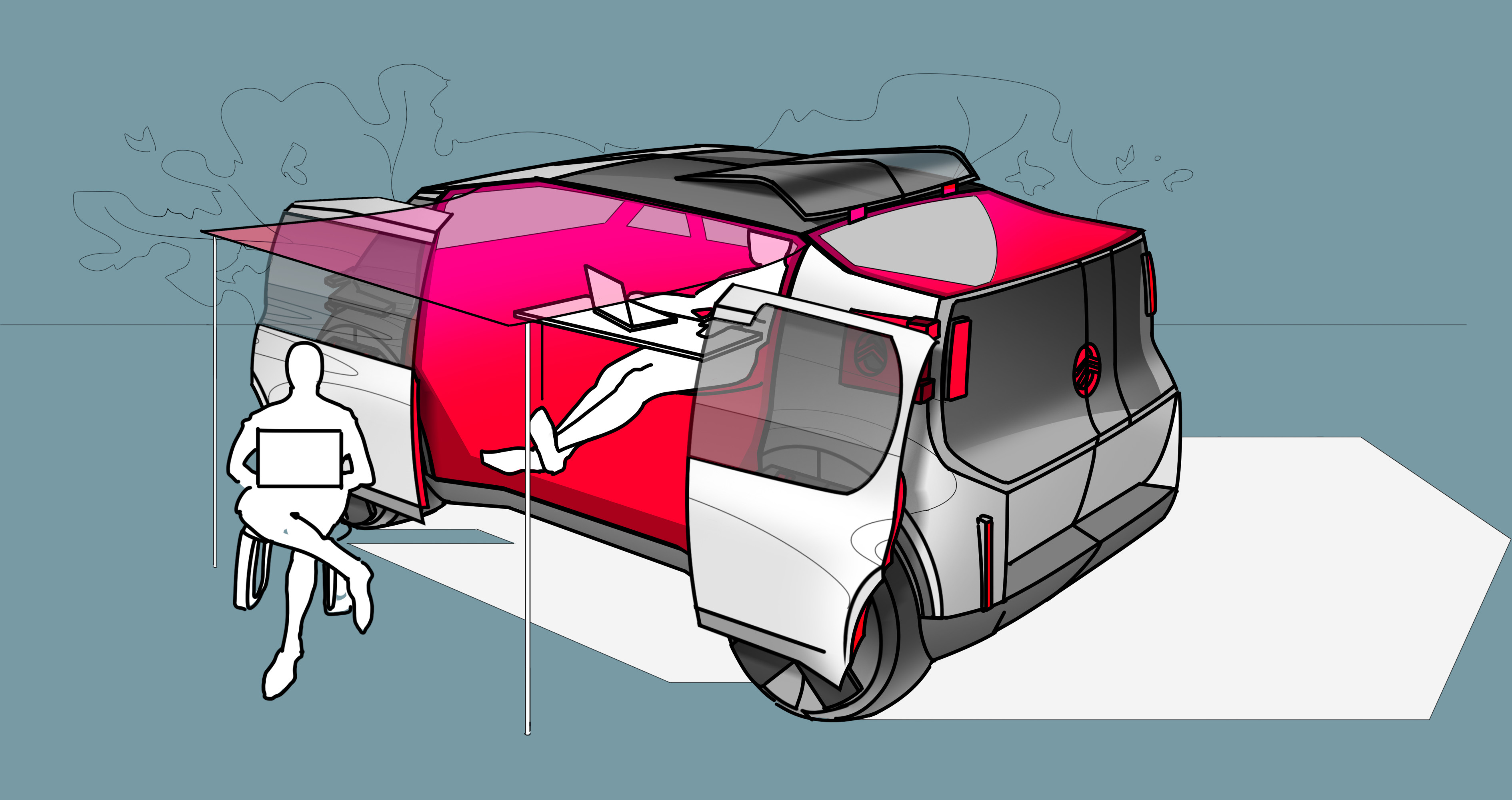

Citroën’s ELO concept car was one of the standout designs of 2025. A collaboration between Citroën and French sportswear retailer Decathlon, the ELO reimagined the people carrier as an ultra-compact, ultra-flexible EV, with bold colours showcasing a highly modular interior.

Wallpaper* spoke to Charles Cambianica, head of product design at Decathlon, along with Madeleine Ternisien, a colour, material and finish designer at Citroën, and Pierre Sabas, head of advanced design and concept cars at Citroën, about the genesis of the project and the innovations it represents.

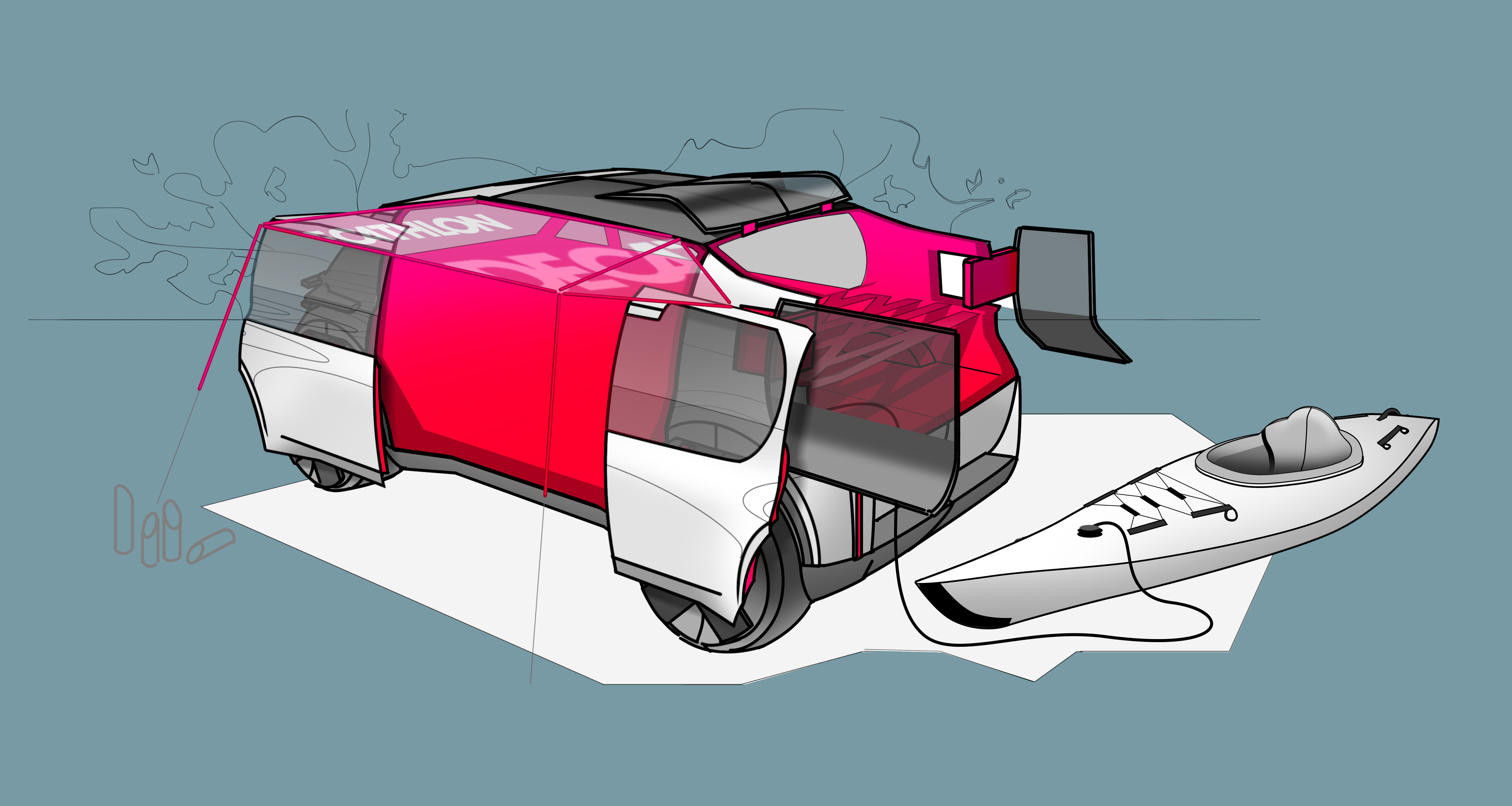

Citroën ELO Concept Car sketches

Wallpaper*: What did you want to get out of the ELO project?

Charles Cambianica, head of product design at Decathlon: Any design is a lab for the future. We and Citroën’s design team wanted to explore a certain scenario and it’s very interesting how we view things from different perspectives.

Our vision is to make sports accessible to as many people as possible, but we also want everyone to get around. We thought there’s a scenario for the future where cars are more than just mobility, so let's figure out how we can help people in their mobility journey.

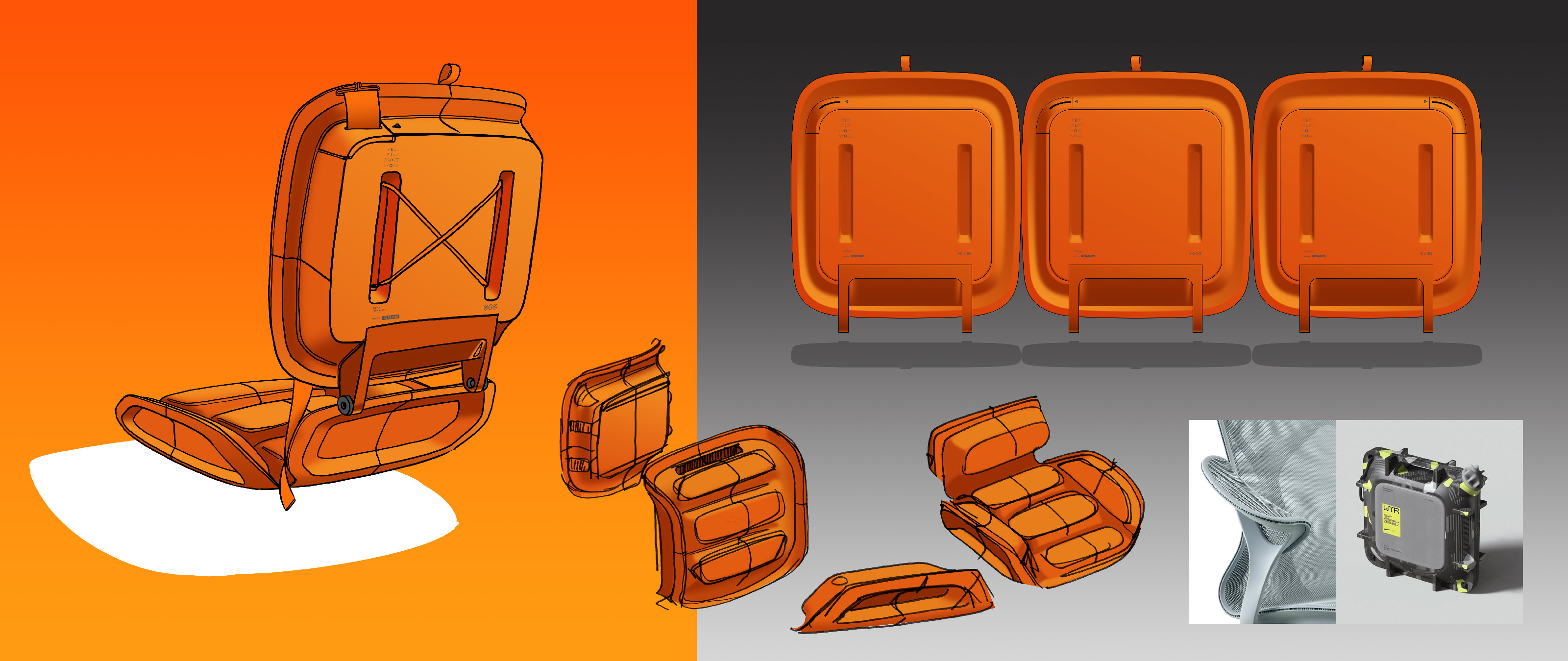

Modular seat design in the Citroën ELO

W*: How is sports equipment design different to automotive?

CC: Our design methodology is a lot about the users. We observe people’s journey in sport deeply: how they behave before, during and after doing it. Our design is very functional, and the automotive industry is very strongly into design and the storytelling of the emotions of shapes. It's very interesting to learn from Citroën’s designers how they approach things, how they develop an idea, the formal vocabulary and emotions because they have strengths we don’t have.

Receive our daily digest of inspiration, escapism and design stories from around the world direct to your inbox.

But during the collaboration, we also realised Citroën’s team is more than this. It was also very interested in scenarios of everyday life. And that’s part of the creative DNA we have in common.

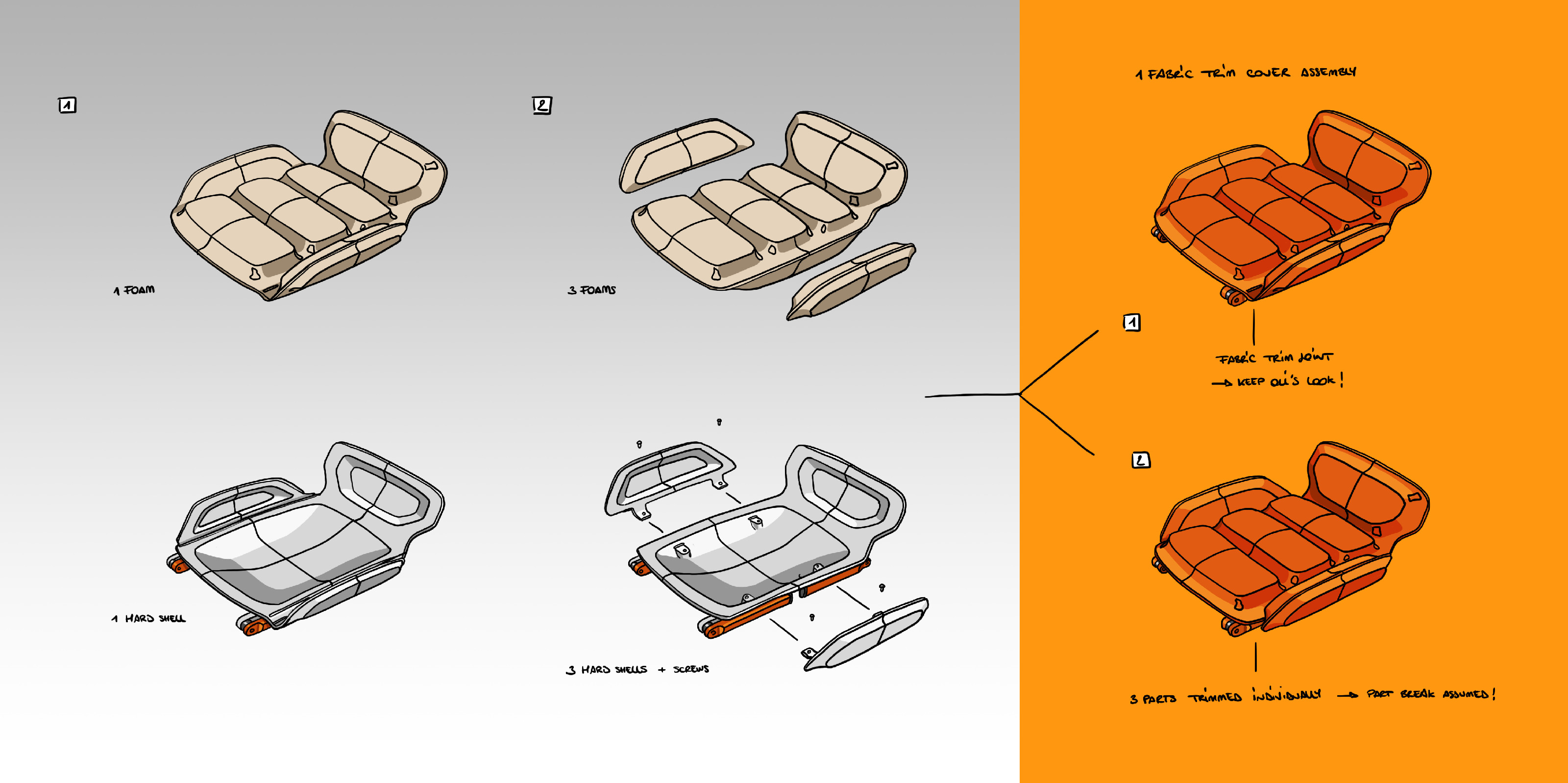

The modular seats take shape

W*: What's your favourite part of ELO?

CC: It's the very small details. I really like the flat surface that makes a sort of bar all around the car. It invites you to live outside the car and interact with. It. The car is no longer just a closed cell. I like the seats you can move outside – we took inspiration for that from the original 2CV. And I particularly like the sill so you can sit on the side of the car when the doors are open. In my daily life I have a car that is much bigger than ELO but I can do so much less with it!

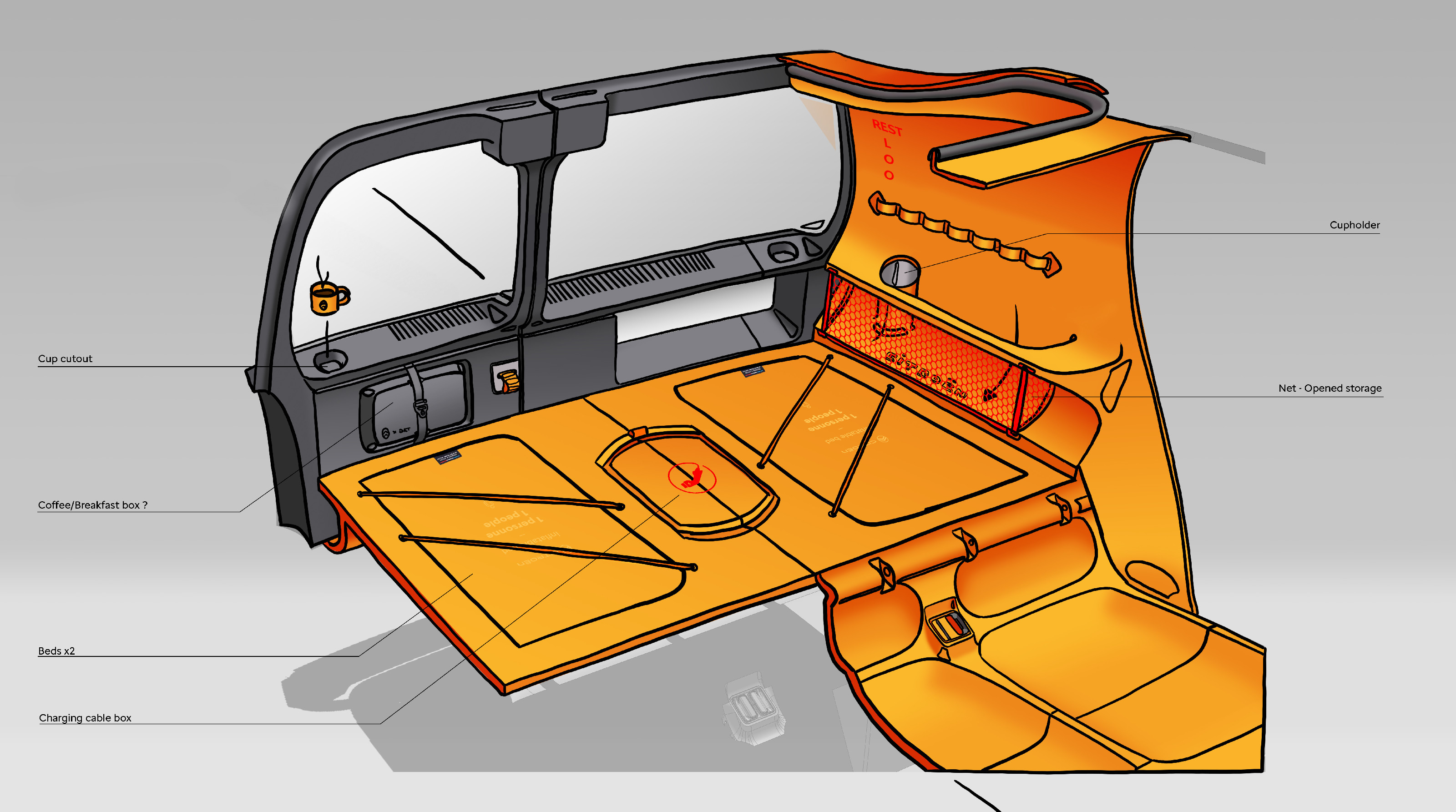

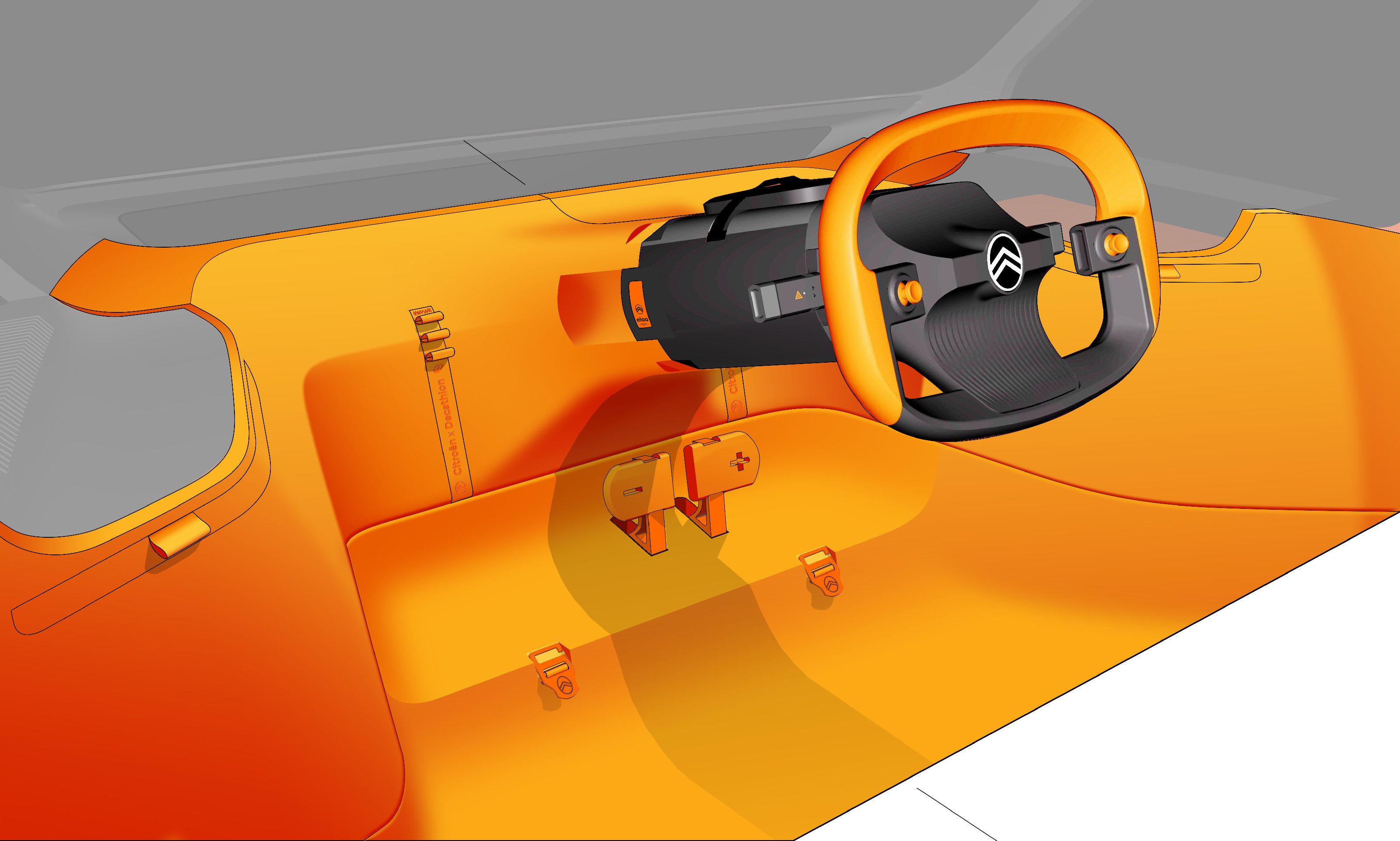

Interior sketches, Citroën ELO Concept

W*: Which are your favourite materials used in ELO?

Madeleine Ternisien, colour, material and finish designer at Citroën: The felt material used on ELO’s doors is something we've been trying to develop for a while. We’d already used the polyfabric felt in the Oli concept and had rolls of it left in our storage area. We shredded it into small pieces, then mixed the fibres together and we got this new material. It’s 100 per cent polyester, 60 per cent recycled with 40 per cent new fibres to ensure it’s got good mechanical properties.

We then put the material between two hot metal plates in the shape we want, and it's pressed out like a waffle machine. I also really like the bumpers.

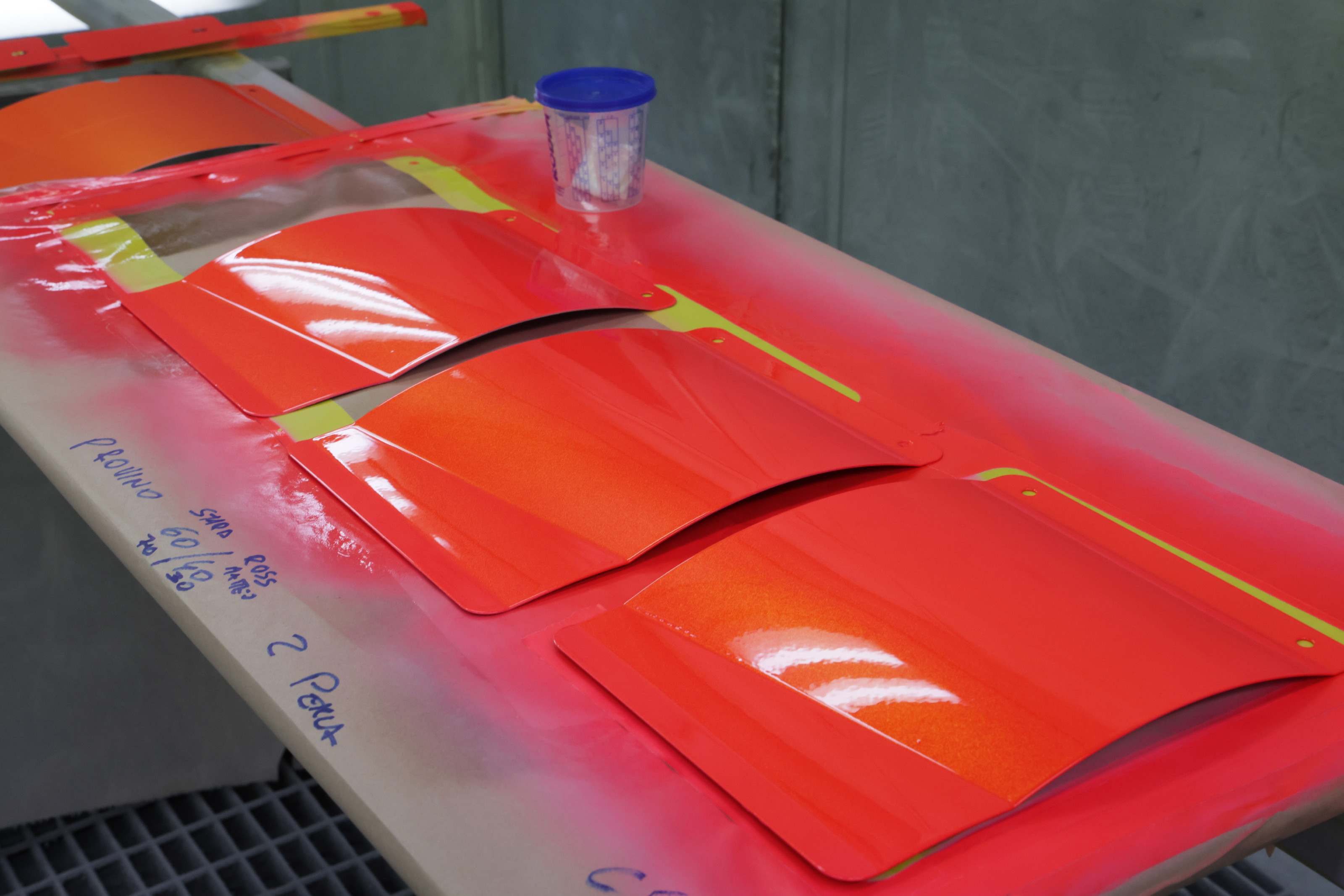

Material samples from the Citroën ELO Concept

The concept takes shape in Citroën's design studio

W*: Why are the bumpers so interesting?

MT: It’s the polypropylene the bumpers are made of. We already use polypropylene for most of the plastic parts in our cars but in ELO, the transformation process is completely different. Instead of injection moulding the raw material as we normally do, we follow the same process as Decathlon uses for making the protective elements of its cycle helmets. The polypropylene granules are heated with steam – a bit like popcorn – and that makes them inflate and stick together.

The ELO Concept offered the chance to work with new materials

It might look like polystyrene but it’s much less brittle and still has air in the cell structure which makes it super lightweight. We calculated by using it on the door panel insert and replacing as many standard injected parts as we could with this material, we could save about 1.2kg per door which on four doors is nearly 5kg. As polypropylene is usually never visible, we thought we’d showcase it in the bumpers. And the front and rear bumpers are identical, which also saves on production costs.

CAD sketch of the ELO's dashboard

W*: Did you discover new materials by working with Decathlon?

MT: Most of the time we’re using their existing materials for different purposes. ELO’s floor covering is the same technology as Decathlon uses in its swimming caps. I saw it in one of their stores and made the connection in my mind. It’s a completely different application that’s more or less the same technology, but in this case, much stronger because it needs to be more durable for the floor. And it’s perfect because ELO is designed for living in, so needs a floor that’s easy to clean.

Material choices for the ELO concept

Shaping the seat components of the ELO

W*: How much more sustainable are these materials?

MT: The way they’re manufactured consumes less energy. But what’s interesting here is if you were to use polypropylene throughout say the door panel, you’d be able to recycle the whole thing because it’s all the same material.

If we used the polyfabric felt to make a map pocket for a door, for example, it’ll be 40 per cent lighter compared to a standard injected polypropylene plastic part. And you also save carbon output because pressing uses less energy than injection moulding.

Colour choices for the ELO concept

W*: How was the design process for ELO different to a regular project?

Pierre Sabas, head of advanced design and concept cars at Citroën: When we do a car at Citroën, we think about our customers, but not in the way Decathlon does. That really opened our minds. The approach we usually have is we know the range of vehicles we want to compete with and the type of vehicle we want to replace, and we design knowing what to improve and what values to carry over.

Citroën ELO Concept sketch

With Decathlon, we took a completely different approach. First, we thought of the overall use scenario without even thinking of it as a car in the traditional sense. Then the exercise was to design a vehicle that helps solve problems or improves what’s already good in people’s lives. With ELO, we really projected ourselves into different usage scenarios and that was really interesting.

A workshop with Decathlon during the Citroën ELO concept design

W*: Do you think there's room to design a more customer-focused car?

PS: Yes, I think it's time to rethink how we design vehicles. The industry is changing with electric cars. If you think about it, electric vehicles get closer to our home because we plug them in there, they can send us energy and they’re less mechanical compared to what we’re used to so it’s an opportunity to rethink how we consume or use cars.

There’s also the environmental pressure, the fact that we don't drive as fast as we used to and what we expect from vehicles is different. All in all, I think it's the moment to shake things up and break the mould.

The concept takes shape in Citroën's design studio

W*: Do you think customers are ready for a car like ELO?

PS: As a car manufacturer, we must look to the future. Our customers may not be ready for ELO in two, three or four years’ time. But in the future beyond that we'll have to find what the next attractive vehicle is. Today we talk a lot about SUVs but one day it’ll probably be something else. Our job is to anticipate that.

Concept cars are great because they’re our opportunity to gauge peoples’ reaction to something that they weren’t necessarily expecting. If we didn’t push the boundaries with a concept car like ELO, we’d never do it with a production car; it's too risky.

Citroën ELO Concept Car

Jonathan Bell has written for Wallpaper* magazine since 1999, covering everything from architecture and transport design to books, tech and graphic design. He is now the magazine’s Transport and Technology Editor. Jonathan has written and edited 15 books, including Concept Car Design, 21st Century House, and The New Modern House. He is also the host of Wallpaper’s first podcast.