Vertical Farm in Copenhagen reimagines sustainable food

We're looking up to tech specialist YesHealth Group and Nordic Harvest for their clever take on the future of food production

The vertical farm has been the holy grail for optimistic urbanists for decades, a way of cramming food-growing capacity into a compact space that’s perfect for serving up supplies to local residents. Self-contained and highly sustainable, promising practically zero food miles and no obvious downsides, why haven’t more high-rise homesteads haven’t been sowed within city limits around the world? The answer is complexity; an array of racks and lights needs to be constantly monitored and fettled to maximise efficiency and economy.

This new Vertical Farm project in Copenhagen is a collaboration between Taiwanese tech specialist YesHealth Group and Nordic Harvest, a Danish start-up dedicated to Vertical Agriculture in all its forms. While it’s unsurprising that this kind of thinking has taken root in space-pressed communities like Taiwan, the Danish company’s approach is rooted in a desire to return over-farmed land to a more natural state. The company points out that in the centuries following the Industrial Revolution Denmark’s forest cover was reduced to just 2 per cent of its land area – prior to this the entire country was densely forested. Even today, with its ultra-efficient forest management, the figure is still just 14 per cent.

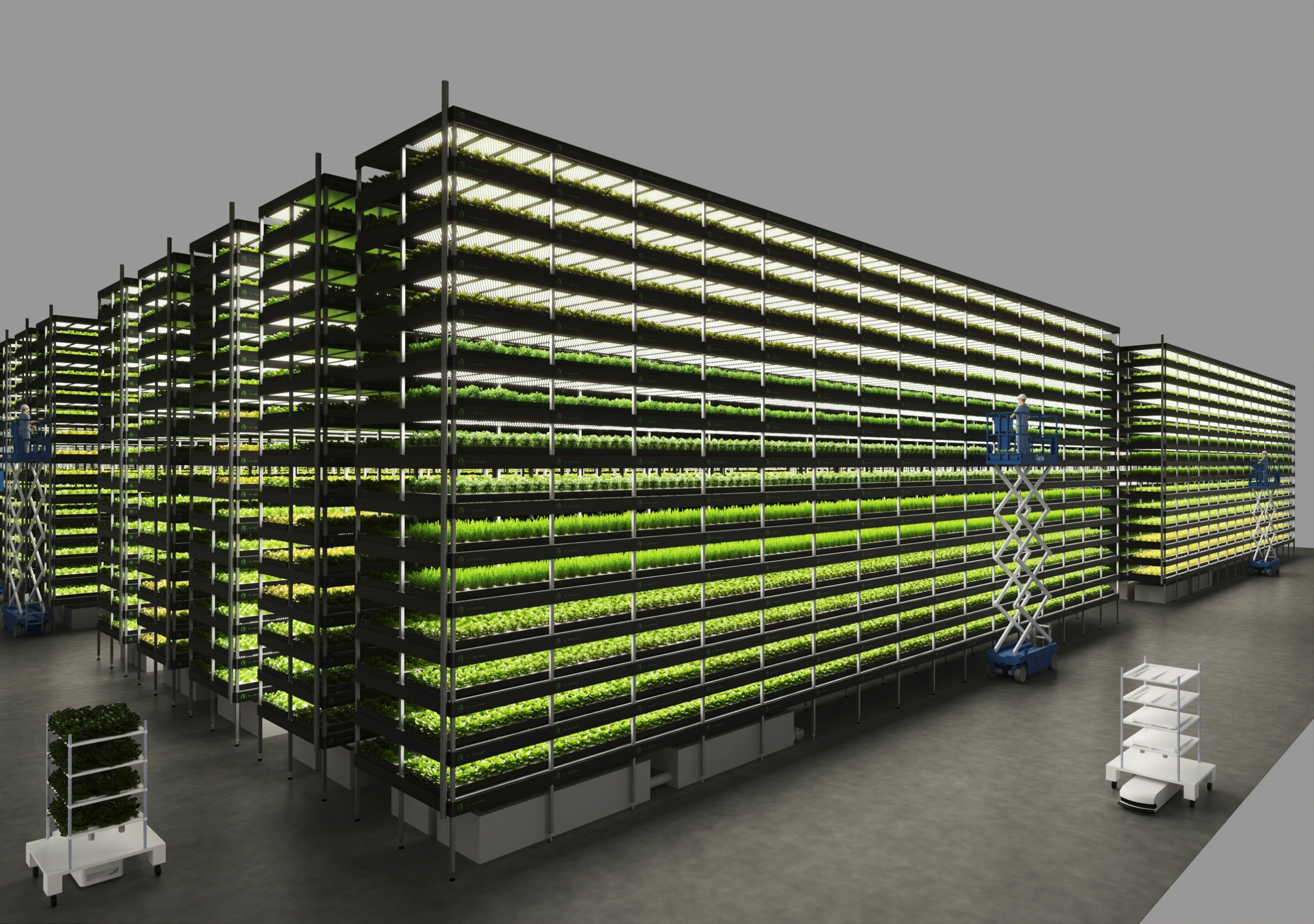

The new vertical farm is located inside the Copenhagen Markets complex, a chunky modern logistic centre designed by CREO Arkitekter in 2015. Rising up 14 ‘storeys’, the high-tech racking is designed for purely robotic operation – planting, nurturing and harvesting. The vast trays take up 7,000 m2 and for the time being are devoted to growing salads and herbs. Technology includes LED lighting, new generation organic substrates and microbial fertilizers and hydroponic systems. Ultimately, Nordic Harvest expect to be growing berries and then root vegetables within five to ten years.

It takes 5,000 LED lights to provide the conditions for efficient growth. Custom software constantly monitors all the relevant levels and patterns to make the process as efficient as possible. When the first harvest is made in early 2021 the vertical farm will have a capacity of about 200-tonnes of produce a year; that’ll soon quadruple as the system beds in. The flipside of hyper-dense urbanism is the space and energy needed to grow and transport food. The vertical farm concept takes a leaf out of big agriculture’s dependence on technology and shutters it away in the big box structures that pepper the fringes of our cities. YesHealth and Nordic Harvest are planning aggressive growth around the world in the coming years. Whether we’ll all reap the benefits of cheaper food and more green space to enjoy is yet to be seen.

INFORMATION

nordicharvest.com

yeshealthgroup.com

Wallpaper* Newsletter

Receive our daily digest of inspiration, escapism and design stories from around the world direct to your inbox.

Jonathan Bell has written for Wallpaper* magazine since 1999, covering everything from architecture and transport design to books, tech and graphic design. He is now the magazine’s Transport and Technology Editor. Jonathan has written and edited 15 books, including Concept Car Design, 21st Century House, and The New Modern House. He is also the host of Wallpaper’s first podcast.

-

Dive into Wes Anderson’s pastel-tinted world in a new exhibition

Dive into Wes Anderson’s pastel-tinted world in a new exhibitionComing to London’s Design Museum in November 2025, ‘Wes Anderson: The Archives’ explores the director's filmography from the 1990s to his recent Oscar-winning picture, accompanied by hundreds of props, models and costumes

-

Modern masterworks from a Paul Rudolph jewel are hitting the auction block next week

Modern masterworks from a Paul Rudolph jewel are hitting the auction block next week'Art from the Bass House' at Christie’s this month is the perfect marriage of art and architecture

-

The Aston Martin DBX S aims to take the brand’s performance SUV to new heights

The Aston Martin DBX S aims to take the brand’s performance SUV to new heightsAston Martin have fettled their SUV to create a new flagship, the DBX S, complete with new lightweight materials and boosted power

-

Noma Projects brings the world’s greatest restaurant into your kitchen

Noma Projects brings the world’s greatest restaurant into your kitchenNoma Projects launches with a smoked mushroom garum for at-home cooking, the first in a series of products and media and environmental programmes set to make the famous restaurant more accessible

-

Vipp launches supper club in converted pencil factory

Vipp launches supper club in converted pencil factoryDanish design brand Vipp has launched a supper club in a former pencil factory in Copenhagen, with a rotating roaster of acclaimed chefs

-

Popl wins Best Burger Bar: Wallpaper* Design Awards 2021

Popl wins Best Burger Bar: Wallpaper* Design Awards 2021Designed by Danish architects Spacon & X, the new Popl in Copenhagen sees the world’s most influential restaurant chart a more populist course

-

Artist’s Palate: Jeppe Hein's ‘Breathe with Me’

Artist’s Palate: Jeppe Hein's ‘Breathe with Me’Take a moment to reflect with the Danish artist’s meditative sharing platter: five South Asian dishes to soothe the mind and body, as featured in our monthly artist’s recipe series

-

Copenhagen’s Empirical Spirits offers a new textured tasting lab

Copenhagen’s Empirical Spirits offers a new textured tasting lab -

Ilse Crawford glazes a Nordic dessert bar with British design flourishes

Ilse Crawford glazes a Nordic dessert bar with British design flourishes -

Own a slice of Rene Redzepi’s Noma restaurant, as its furnishings go under the hammer

Own a slice of Rene Redzepi’s Noma restaurant, as its furnishings go under the hammer -

Essential utensils: Hay teams up with Frederik Bille Brahe on kitchen range

Essential utensils: Hay teams up with Frederik Bille Brahe on kitchen range