Clear view: the use of sapphire crystal heralds a dazzling new era in fine-watch design

Receive our daily digest of inspiration, escapism and design stories from around the world direct to your inbox.

You are now subscribed

Your newsletter sign-up was successful

Want to add more newsletters?

Daily (Mon-Sun)

Daily Digest

Sign up for global news and reviews, a Wallpaper* take on architecture, design, art & culture, fashion & beauty, travel, tech, watches & jewellery and more.

Monthly, coming soon

The Rundown

A design-minded take on the world of style from Wallpaper* fashion features editor Jack Moss, from global runway shows to insider news and emerging trends.

Monthly, coming soon

The Design File

A closer look at the people and places shaping design, from inspiring interiors to exceptional products, in an expert edit by Wallpaper* global design director Hugo Macdonald.

Richard Mille was a pioneering force in this area of horological design, while MB&F, Greubel Forsey and Hublot are increasingly pushing the boundaries of form and cutting technology. Not only does the use of sapphire crystal result in a visually arresting watch housing, but its toughness is almost unrivalled. ‘It can only be marked by a diamond, so it stays beautifully transparent, without any scratches,’ says Ricardo Guadalupe, Hublot’s CEO.

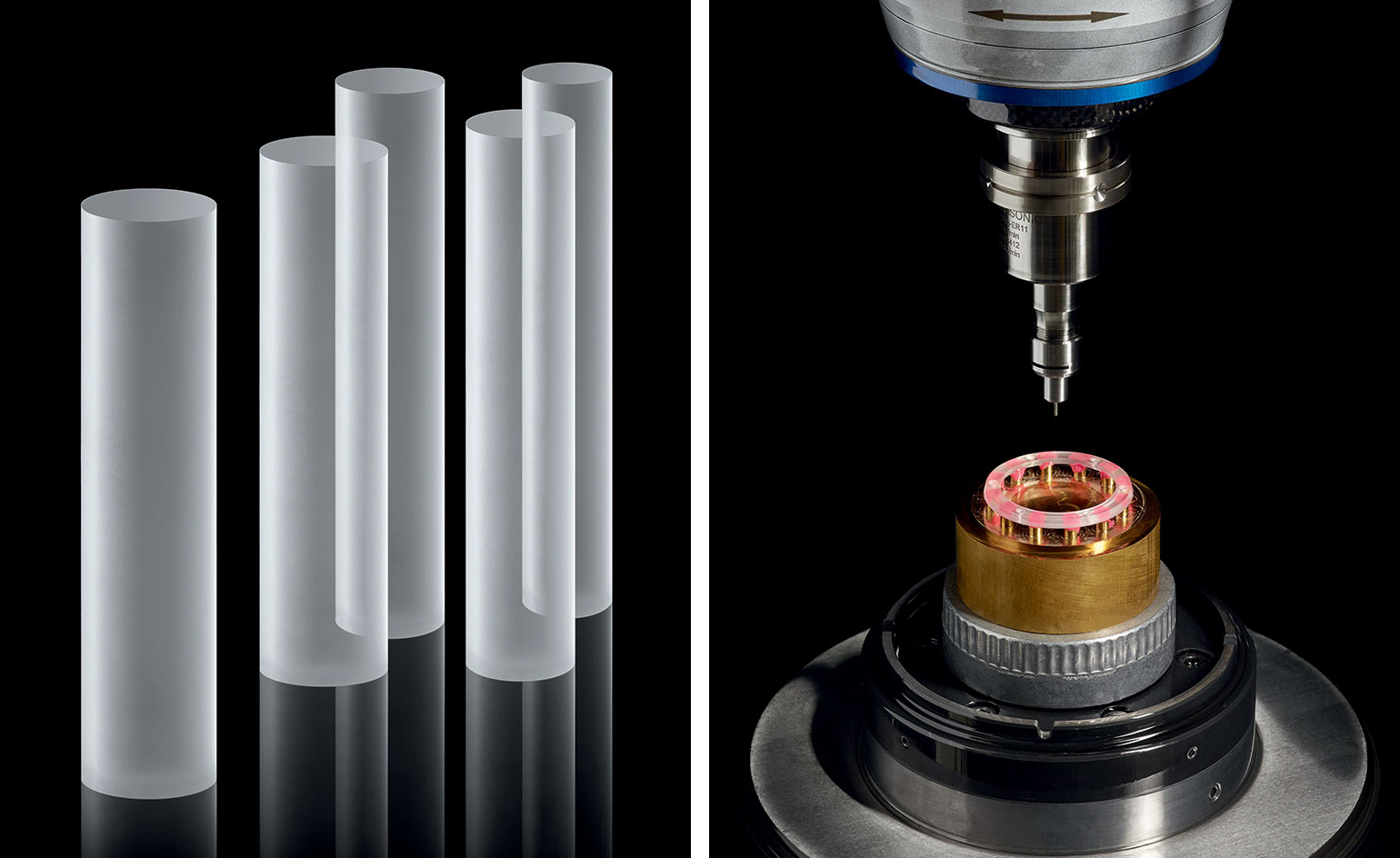

Synthetic sapphire, the base material, is grown in laboratories using a melted mixture of aluminium oxide that, on cooling, forms crystal cylinders known as ‘boules’. Its scratch resistance makes it popular as a ‘glass’ in industrial design; it is used in barcode scanners, laser rods and new-generation iPhones to protect the camera lens. Watch cases, however, are an entirely different affair, demanding more complicated shapes, water resistance and a fine finish.

Sapphire crystal’s extreme hardness is countered by a susceptibility to chipping, cracking or shattering. ‘The manufacturing process is long and complicated,’ Guadalupe says. ‘There can be a lot of breakage, and we need to restart the process many times from the raw material, to have the perfect shape and colour.’

Cutting and shaping a case is a seven-step process. The raw material is cut according to the final product size. It is then ground to the general shape, followed by CNC drilling of the required holes. CNC is used again to cut different case forms. Next, sandblasting finishes the holes, followed by fine polishing and, lastly, final polishing. The time-consuming polishing stages require extremely high-quality diamond powders.

For Hublot’s ‘Big Bang Unico Magic Sapphire’ chronograph, it sought the expertise of a Swiss sapphire crystal specialist, who collaborated with its horological engineers. The titanium screws and crown complement the look. Water-resistant to approximately 100m, with a power reserve of around 72 hours, this limited-edition timepiece has a production run of just 500.

As originally featured in the Precious Index, our new watches and jewellery supplement (see W*218)

Left, polishing is done with a high-quality diamond powder. Right, the 'Big Bang Unico Magic Sapphire' chronograph with polished sapphire crystal case and bezel, and skeleton dial

INFORMATION

‘Big Bang Unico Magic Sapphire’, price on request, by Hublot. For more information, visit the Hublot website

Receive our daily digest of inspiration, escapism and design stories from around the world direct to your inbox.