Made in London dives into the city’s rich collection of 21st-century factories

Made in London is a photographic journey through the capital’s surprisingly rich and diverse manufacturing scene, capturing everything from aircraft interiors to cardboard boxes, and everything in between

Carmel King - Photography

Made in London is a photo essay that will confound urban pessimists. The subject of this design book is London’s manufacturing scene, not 50 or 100 years in the past, but now, in the present day. Shot by photographer Carmel King, with an introduction by Mark Brearley and texts by regular Wallpaper* contributor Clare Dowdy, Made in London travels the length and breadth of the capital to find makers big and small from a rich diversity of industries. Brearley – professor of urbanism at London Metropolitan University and a former head of design for London at the GLA – is also owner of Kaymet, a south London manufacturer of spare and simple aluminium trays and trolleys.

Kaymet has made aluminium trays in south London since 1947.

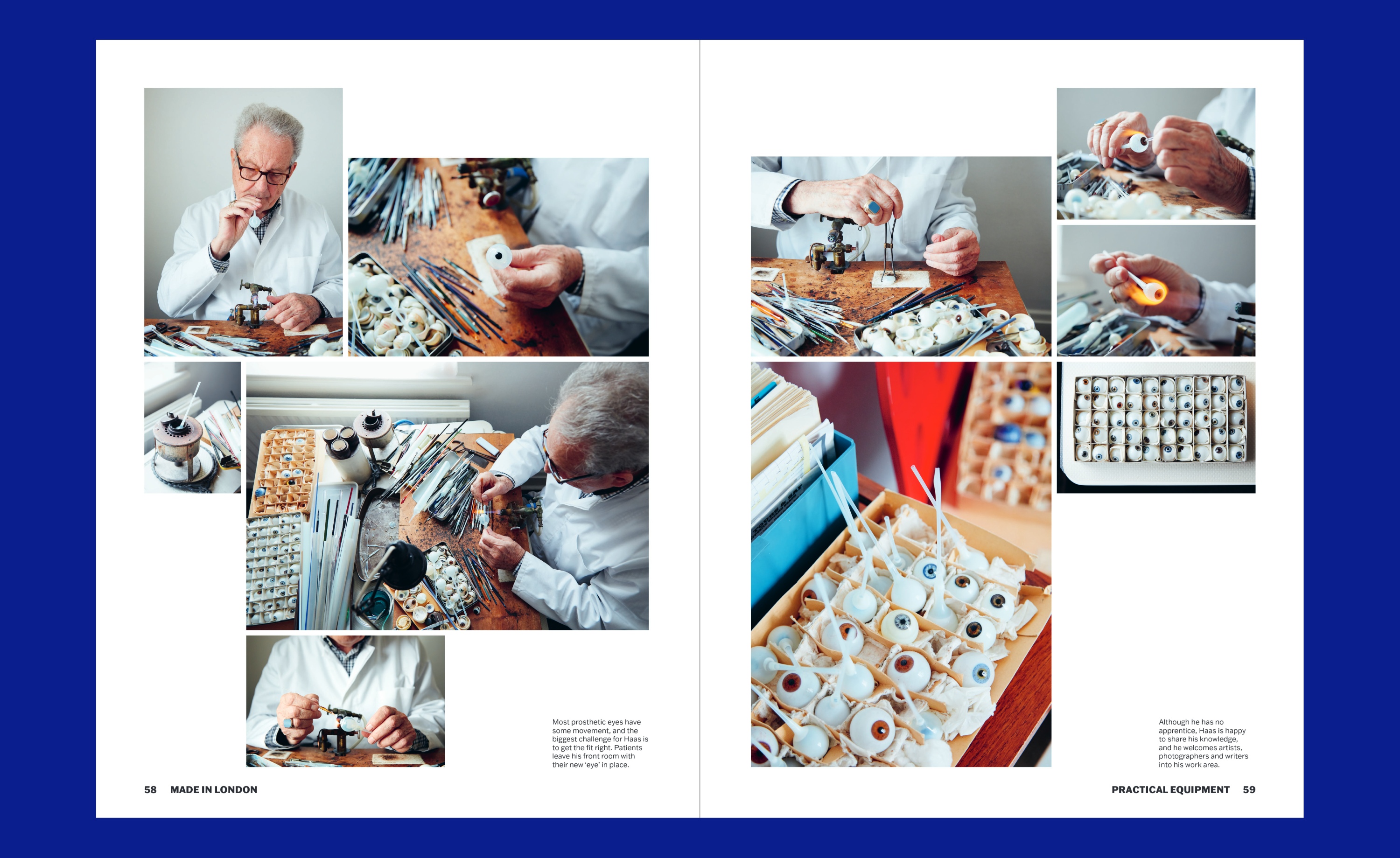

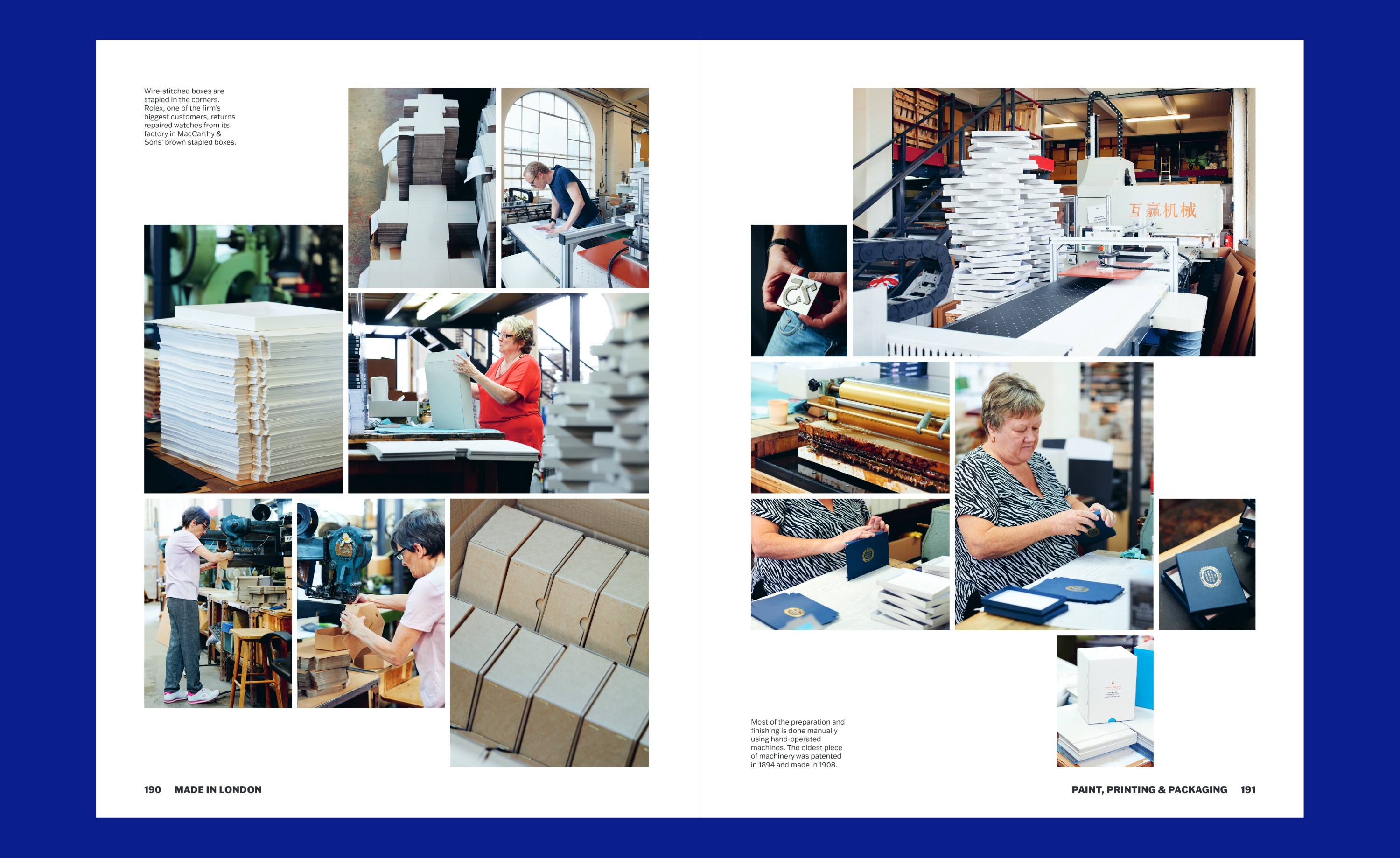

It’s this kind of niche business that still excels, whether it’s making paint tins for Farrow & Ball, crafting glass eyes for the NHS, meticulously shaping ballet shoes, growing salad, or brewing beer.

Jost Haas handmakes glass eyes in his front room in Mill Hill.

Although the capital is visibly scarred by the remnants of former industry, both heavy and light, pockets of manufacturing still exist.

The book contains 50 businesses in all, ranging from tiny cottage industries like Jost Haas’s glass eye workshop in Mill Hill to the thriving Brompton factory in Greenford, which makes 75,000 folding bicycles every year.

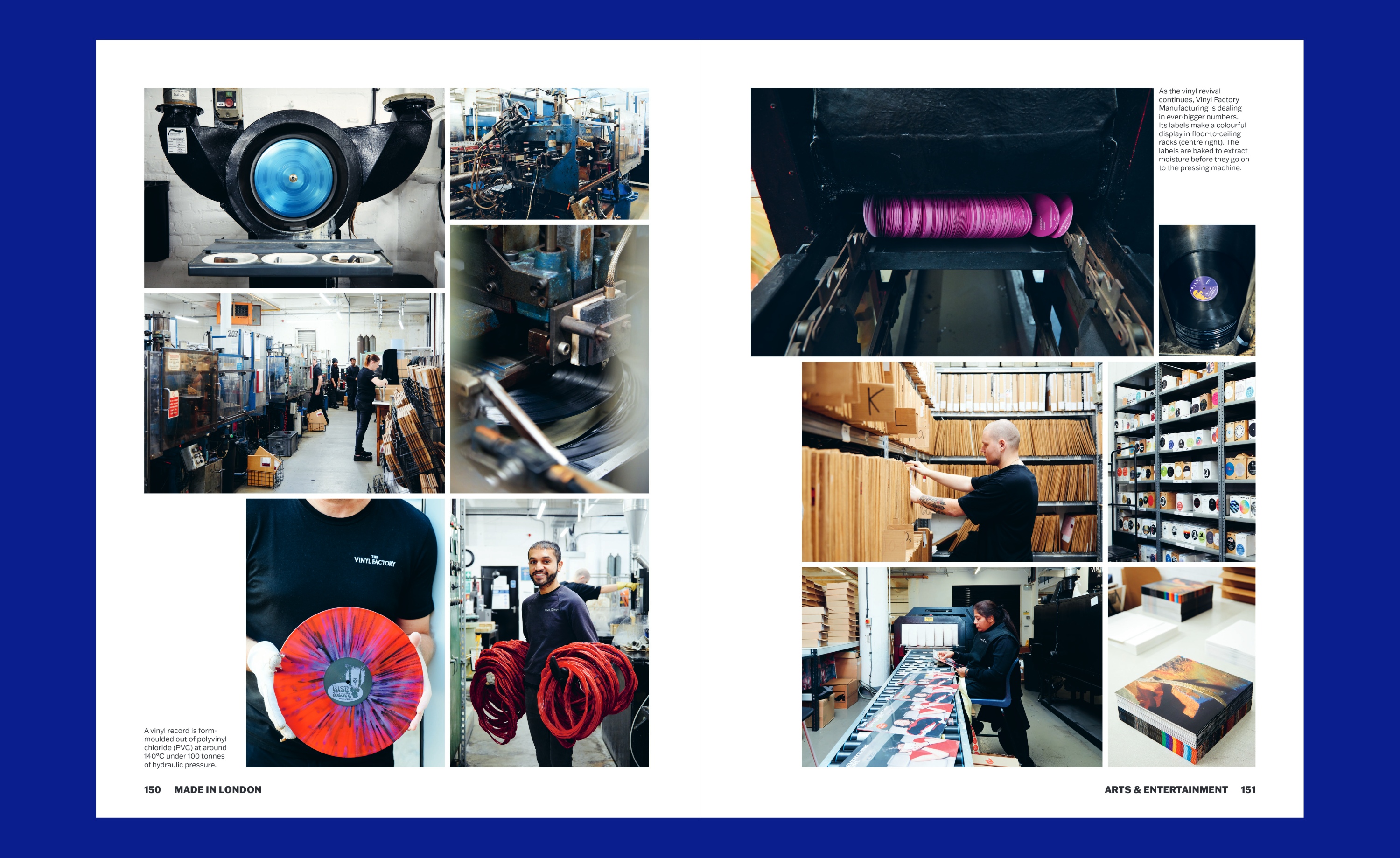

The Vinyl Factory in Hayes has benefited from the boom in record collecting.

Brearley notes in his introduction that London’s 32 boroughs contain around 4,000 different manufacturers, so this book is necessarily a very small sliver of what’s out there.

As you might expect, there’s a concentrated dose of high-end luxury, in the shape of tailoring, taps, fine stone, hand-printed wallpaper and art glass. But there are also everyday items like tin cans, wire, paint, and even treacle, the last produced at Tate & Lyle’s massive 50-acre site in Silvertown, which makes half of all sugar sold in British shops.

W MacCarthy & Sons is a fifth-generation family business making high-end packaging.

Often, these case studies are tales of perseverance against the odds. Changing tastes, changing demographics, and – most crucial of all – the ever-escalating cost of London real estate, have conspired against all but the hardiest small business.

Receive our daily digest of inspiration, escapism and design stories from around the world direct to your inbox.

The survival of these 50 firms, and the diversity of their output, is testament to the shifting focus of modern manufacturing, and the ongoing importance of industry to the life of a major city.

INFORMATION

Made in London: From Workshops to Factories by Carmel King and Mark Brearley with additional texts by Clare Dowdy

£40, Merrell Publishers, MerrellPublishers.com

Jonathan Bell has written for Wallpaper* magazine since 1999, covering everything from architecture and transport design to books, tech and graphic design. He is now the magazine’s Transport and Technology Editor. Jonathan has written and edited 15 books, including Concept Car Design, 21st Century House, and The New Modern House. He is also the host of Wallpaper’s first podcast.

-

Usher opens up about breakfast playlists, banana pudding and why a glass tumbler is always on his rider

Usher opens up about breakfast playlists, banana pudding and why a glass tumbler is always on his riderOn the heels of a collaboration with Baccarat, the Grammy-winning singer-songwriter breaks down his entertaining tips. 'Hosting is an expression of how you feel about your guests and also who you are.'

-

The beauty trends that will define 2026, from ultra-niche fragrances to anti-ageing dental care

The beauty trends that will define 2026, from ultra-niche fragrances to anti-ageing dental careAs we enter the new year, we speak to experts in fragrance, skincare, aesthetics, wellness and more about the trends that will be shaping the way we look

-

The most stylish hotel debuts of 2025

The most stylish hotel debuts of 2025A Wallpaper* edit of this year’s defining hotel openings. Design-led stays to shape your next escape

-

Bees can now check in at Kew’s new pollinator hotel

Bees can now check in at Kew’s new pollinator hotelAt Wakehurst, Kew’s wild botanic garden, artist Kristina Pulejkova unveils four functional sculptures that tell the hidden story of seeds and act as a refuge for bees during the heat of summer

-

Lulu Harrison is the Ralph Saltzman Prize winner 2025

Lulu Harrison is the Ralph Saltzman Prize winner 2025The Design Museum, London, announces Lulu Harrison as winner of The Ralph Saltzman Prize for emerging designers, and will showcase her work from 24 June to 25 August 2025

-

‘Designers are far more than just producers of commercial goods’: Samuel Ross on the London Design Biennale

‘Designers are far more than just producers of commercial goods’: Samuel Ross on the London Design BiennaleThe artistic director of the major event and founder of A-COLD-WALL* discusses the role of a designer and the future of the sector in an exclusive interview

-

London Craft Week 2025 highlights – what to see this weekend

London Craft Week 2025 highlights – what to see this weekendLondon Craft Week 2025 (until 18 May) brings together some 1,000 established and emerging makers. Here is everything we saw and loved so you don't miss a thing

-

Erasers become architectural illusions at Gallery Fumi

Erasers become architectural illusions at Gallery FumiLondon duo Study O Portable unveil 'Rubber Rocks', trompe-l’œil furniture made from erasers, exploring themes of materiality, memory and architectural decay

-

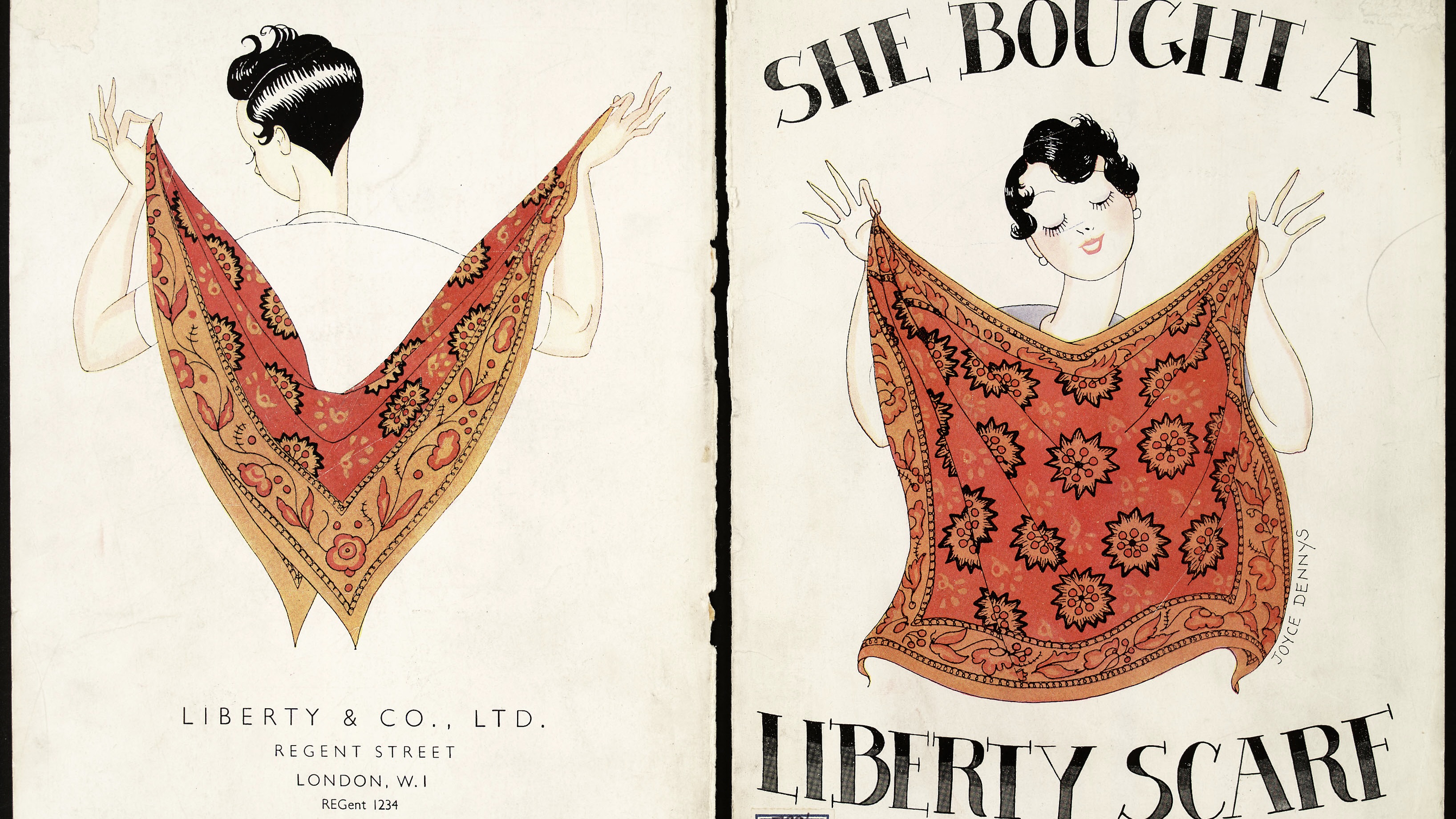

Liberty at 150: a history of the brand in 10 objects

Liberty at 150: a history of the brand in 10 objectsLiberty is marking its 150th anniversary; to celebrate, we remember products and prints that helped make the department store the cultural touchpoint it is today

-

A first look inside the new Oxford Street Ikea. Spoiler: blue bags and meatballs are included

A first look inside the new Oxford Street Ikea. Spoiler: blue bags and meatballs are includedThe new Oxford Street Ikea opens tomorrow (1 May), giving Londoners access to the Swedish furniture brand right in the heart of the city

-

What to see at London Craft Week 2025

What to see at London Craft Week 2025With London Craft Week just around the corner, Wallpaper* rounds up the must-see moments from this year’s programme