Metal gurus: Uniform Wares' tech-savvy take on the fabric watch strap

‘As designers, we’ve became used to instinctively working within the limitations of manufacturing methods,’ says Michael Carr, creative director of British watch brand Uniform Wares. Now, however, a new manufacturing method devised to produce an entirely new type of watch strap, has freed them from these restraints.

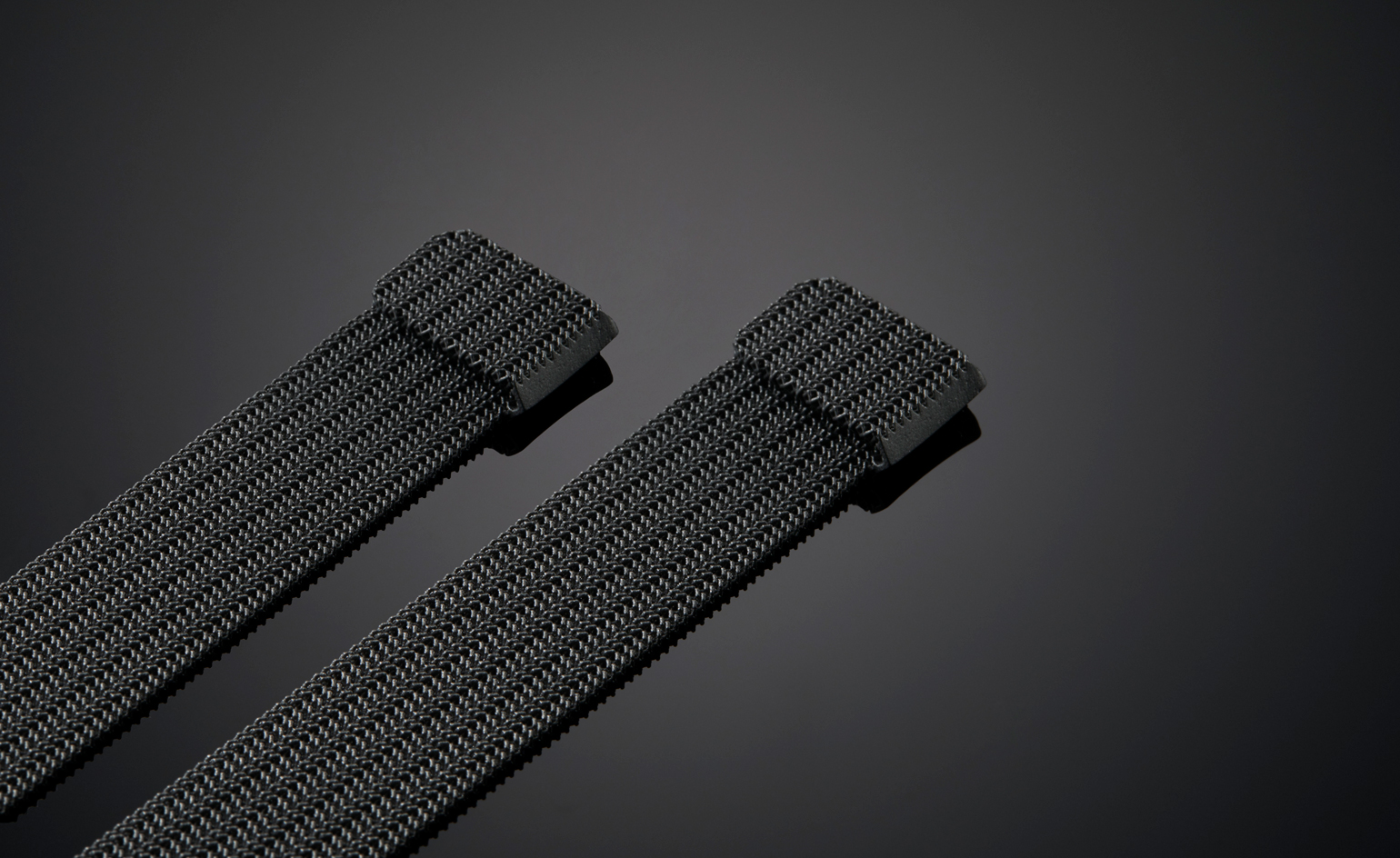

The brand has collaborated with east London-based manufacturer Betatype, which works more commonly with the aviation, motorsport and medical industries, on a laser powder-fusion process to create a titanium mesh. The Nato-style weave consists of a continuous piece of mesh material formed from over 4000 interlocking links, meaning it is a highly resilient metal bracelet, yet as soft as fabric on the wrist.

‘The reason we started with the watch strap is because it seemed to us to be the design aspect most in need of a rethink in each design,’ says Carr. ‘Not only is it one of the most critical parts of the watch from a functional perspective, it is also the part which seems to have changed the least since the invention of the wristwatch.’ Two variations of the strap – one, a two-piece bracelet version that fits the M-Line series of watches, and the other a one-piece style that works with the C-Line family – are available to purchase separately from their website.

This new method of manufacturing straps obviously promises further creative potential as it presents a chance to produce a much wider range of forms and shapes without the need to consider dead space and cavities. ‘That wouldn’t be possible using traditional manufacturing methods,’ Carr points out. It also offers the possibility of re-using most of the discarded material. Simply folding the strap back on itself will secure the watch, while just pulling the strap through to fit effortlessly adjusts the size. ‘We realised that where we made the weave solid, we could also add in microscopic teeth allowing the strap to grip to itself, a bit like Velcro,’ says Carr. That, happily, led to another design benefit – a seamless strap with no apparent clasp, taking Uniform Wares signature minimalist aesthetic to a whole new level.

The titanium mesh straps are constructed on the build plate

Uniform Wares + Betatype titanium mesh Nato bracelet with C36 watch

INFORMATION

’Materials: Process and Development in Design,’ 17 - 20 September, 83 - 85 Paul Street. uniformwares.com

Receive our daily digest of inspiration, escapism and design stories from around the world direct to your inbox.

Hannah Silver is a writer and editor with over 20 years of experience in journalism, spanning national newspapers and independent magazines. Currently Art, Culture, Watches & Jewellery Editor of Wallpaper*, she has overseen offbeat art trends and conducted in-depth profiles for print and digital, as well as writing and commissioning extensively across the worlds of culture and luxury since joining in 2019.