Techno tailor: Boss is revolutionising the made-to-measure suit

Some 90 per cent of Hugo Boss’ income is generated by menswear, and – despite critically acclaimed Boss womenswear collections from Jason Wu over the last four years – the Metzingen-based company has recently decided to re-focus on its roots.

In a first attempt to refresh the core business, the womenswear show at the recent New York Fashion Week was cancelled and a men’s show added to the calendar. The last time Boss held a menswear presentation was also in New York, in 2008. The label was the predominant global supplier of what then seemed an unimpeachably modern uniform for successful, modern men. It was a suit – the hallmark of the brand – cut tight, but rendered flexible with elastane and German know-how.

The confidence of the label’s name perfectly fitted the macho-filtered ambition of the time. But times have changed, the suiting index has plummeted, and thus the label’s latest outing, for A/W17, represented a total refresh: the number of suits was moderate, and most were paired with athletic-inspired zip-up sweaters with oversized ring details.

Customer orders are sent through to the Metzingen technical centre, where the order is created mainly by machine, and finished by hand

Call this ‘athleisure’-inflected formalwear. Call this Boss 2.0. But in the traditionally conservative men’s fashion market, the brand has notably invested in the latest in German engineering and technology to enhance its made-to-measure collection. The line was introduced in 2011 with dedicated floors in the Frankfurt and Zurich flagship stores, and has since been a global hit. Customers can order personalized and partly handcrafted suits starting at €1,700. The quality of fit and fabrics aspires to the Savile Row benchmark.

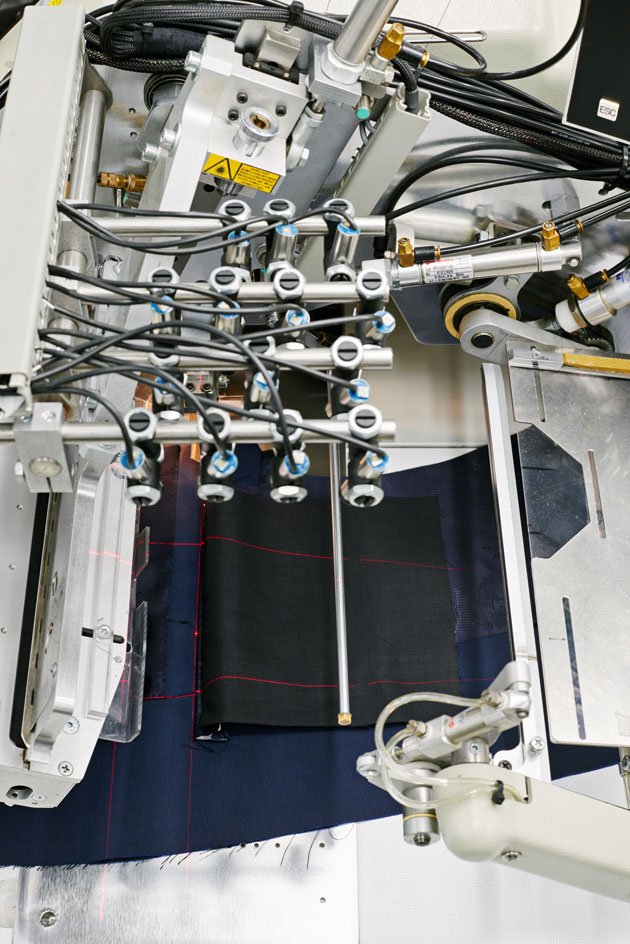

Boss is continually investing in what it calls a ‘technical centre’. It is an incommensurable collection of the latest laser and sewing technology that can meticulously mimic handcraft, but with flawless results. Boss engineers have created specific machines for almost all the tailoring steps traditionally done by hand, combining the knowledge of its seamstresses with the latest tech. This guarantees the most precise quality without losing the individual appeal. A gimp buttonhole of a Boss made-to-measure suit looks handmade, but is now created by a computer; the 180 pieces of a suit are cut by laser machines, allowing pinstripes and Prince-of-Wales checks to appear seamless when the suit is put together. The lining, though, is still done by hand, for ultimate comfort. At least, until the Boss engineers have constructed the right machine.

As originally featured in the April 2017 issue of Wallpaper* (W*217)

All 180 pieces of a suit are cut by laser machines, allowing pinstripes and Prince-of-Wales checks to appear seamless when the suit is put together.

The vast array of machines are in control of every aspect of the tailoring steps traditionally made by hand, apart from the lining which is still handmade for ultimate comfort

The latest laser and sewing technology mimics handcraft techniques with flawless results, limiting the chance of human errors

The Metzingen site is used as a development and a production facility. Apart from prototypes and sample pieces, its Technical Center mainly produces suits, jackets and trousers

INFORMATION

For more information, visit the Hugo Boss website

Receive our daily digest of inspiration, escapism and design stories from around the world direct to your inbox.