Bespoke Partnership

Change Maker Hanson Cheng is reinventing the wheel to help fight pollution

With clean tech start-up The Tyre Collective, Hanson Cheng plans to reduce pollution from tyre wear by capturing and repurposing the waste particles

In partnership with E.ON

Tyres wear, but where does that wear actually go? That’s the question posed by Hanson Cheng, Hugo Richardson and Siobhan Anderson, co-founders of The Tyre Collective, a clean tech start-up, building a device to capture and repurpose tyre wear waste.

Despite being virtually invisible, tyre wear, Cheng will tell you, is actually the second largest microplastic pollutant in our oceans and a considerable contributor to global air pollution. Every time the wheels of our cars and motorbikes make contact with a road surface, particularly during friction-intensive moments of braking, cornering and accelerating, microscopic particles of rubber are worn off the tyres.

But while the matter is microscopic, the effect is massive, potentially lethal even. Right now, says Cheng, it’s estimated that there are over one million tonnes of tyre wear debris strewn annually on European road surfaces and damaging the surrounding environment. Tyre wear accounts for up to half of PM2.5 emissions from road transport (that is, emission particles of 2.5 microns or less, small enough to travel deeply into the respiratory tract).

‘Tyre wear is a stealthy pollutant,’ says Cheng. ‘It gets into waterways and is proven to be toxic to marine life. It’s also small enough to enter the air breathed by humans.’

An experiment underway in the workshop

Driven by a desire to challenge existing ideas and conventional ways of doing things, Cheng addresses sustainability via design. He is focused as much on changing mindsets as on changing tyres.

Cheng in the workshop

‘When we talk about zero emissions, we tend to focus on exhaust emissions, but that's really only half of the problem. Yes, exhaust emissions are set to reduce with the growing popularity of electric vehicles, but tyre wear is projected to increase due to added battery weight and increased torque. In order to really reach true net-zero emissions on vehicles, we really have to address non-exhaust emissions also – tyre wear and brake wear,’ says Cheng.

‘As we move towards an electric future, it’s crucial to consider the implications of tyre wear, so we’re not replacing one pollution source with another.’

With Cheng now looking to reduce the environmental impact of electric vehicles (EVs), The Tyre Collective has decided, in effect, to reinvent the wheel. ‘Redesigning a tyre,’ he says with a smile, ’is a very complex thing.’

So, how are they doing it? ‘The Tyre Collective aims to mitigate tyre emissions by capturing them at source to help ensure cleaner air. What we're designing is a box that sits behind the wheel. As you’re driving, the little particles coming off the tyres are pulled out of the air by our device.’ In the lab, The Tyre Collective’s ingenious little box captures about 60 per cent of all airborne particulates. ‘It’s like a catalytic converter for tyre wear,’ says Cheng.

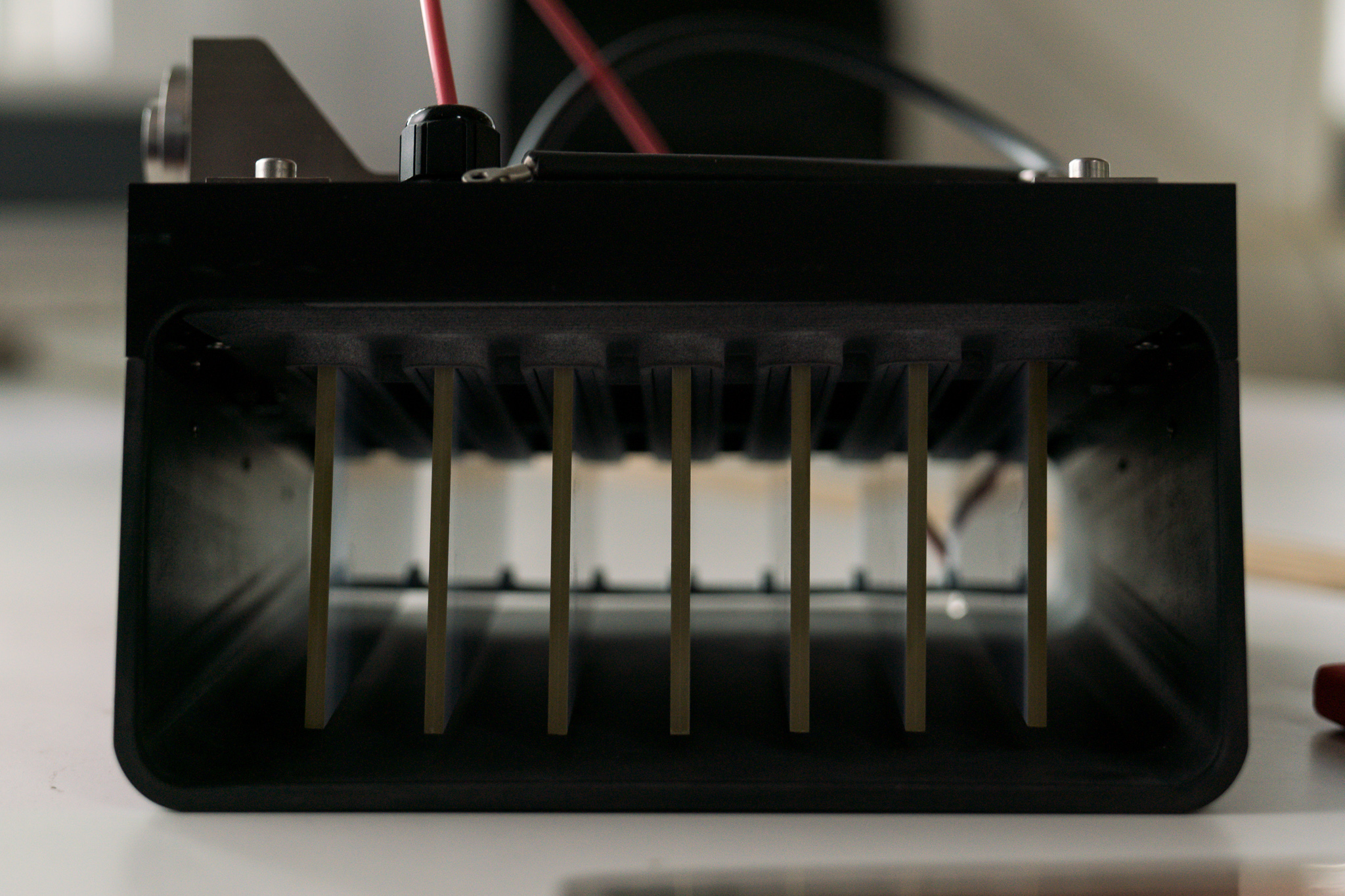

The Tyre Collective’s device, which sits behind a wheel to collect waste particles caused by tyre wear

‘We discovered that tyre particles are charged from friction with the road,’ he adds. What started off with the simple science of rubbing a balloon against a sweater, eventually led to a device that directs and collects charged particles with electrostatics. Fragments are then processed and can be reused, creating a closed-loop system. Tyre wear is a form of micronised rubber that can be reused in a variety of applications such as tyre treads, 3D printing and soundproofing.

The Tyre Collective’s vision is to see a day when the device is installed on every vehicle – either retrofitted or ready integrated – so when you buy a new EV, the rubber particle management system is already central to the vehicle’s performance and driving experience.

‘I think sustainability has always been a part of the way I work,’ says Cheng. ‘And materials play a large role in that. Thinking about not just the product itself, but also the system around it. That's core to my practice. Through design we have an opportunity to imagine something different.’

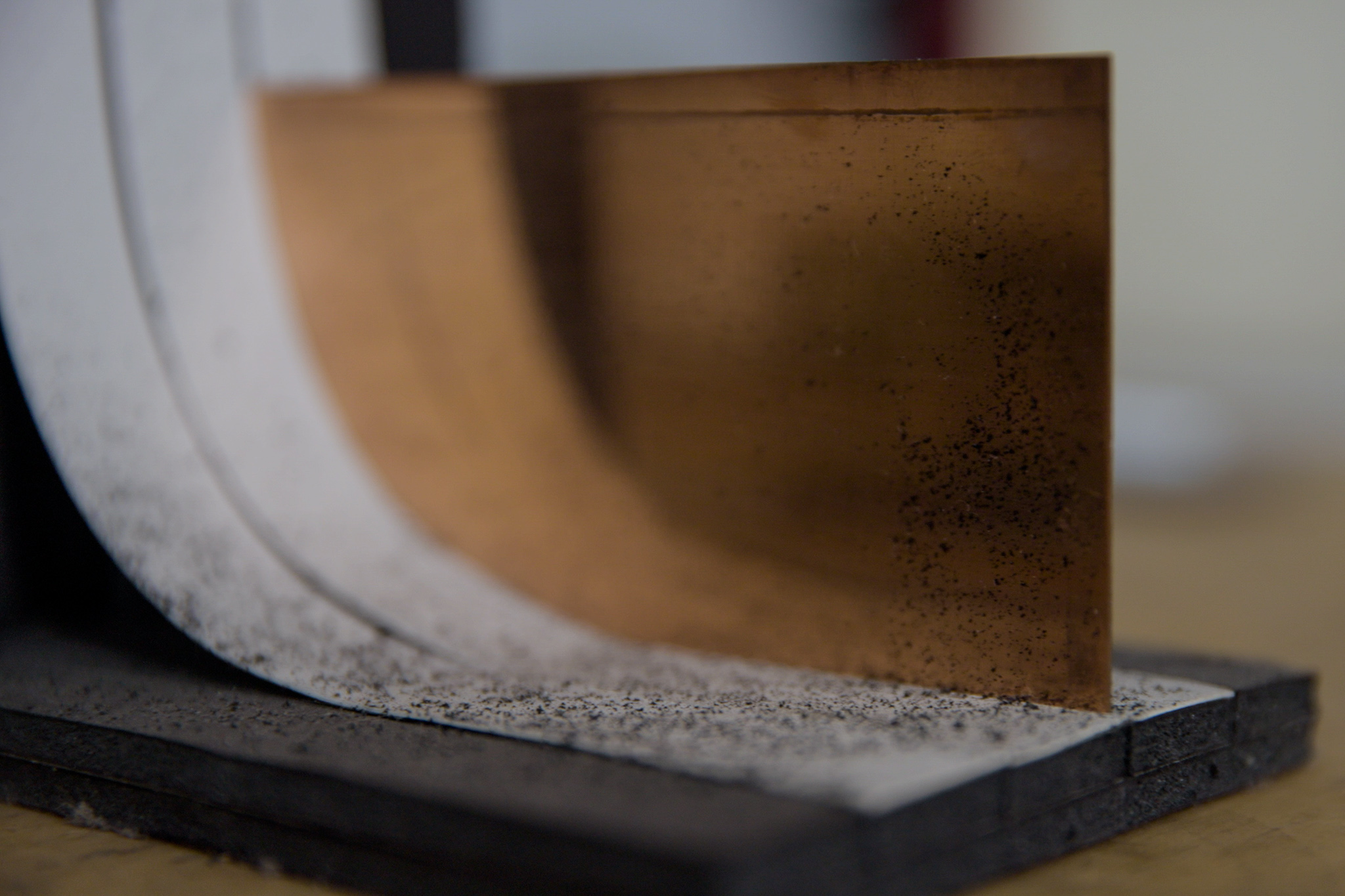

Collecting rubber particles in the workshop

To Cheng, innovator and maverick thinker, a Change Maker is someone who is not afraid to develop their own ideas and challenge existing norms. ‘I take action for climate by using my work to showcase ways of addressing the lack of sustainability across all scales of design. I create solutions to inspire others. If you want to take action for climate yourself – if you have an idea – I urge you to pursue it, talk to others about it. By talking about your ideas, that's how you develop. That’s how you make a change and make an impact.’

Tyre wear particles in The Tyre Collective workshop

Cheng with his dog

Meet more Change Makers – people who are taking action for climate – at eonenergy.com

Receive our daily digest of inspiration, escapism and design stories from around the world direct to your inbox.

Simon Mills is a journalist, writer, editor, author and brand consultant who has worked with magazines, newspapers and contract publishing for more than 25 years. He is the Bespoke editor at Wallpaper* magazine.

-

Sound and Vision: inside Jason Bruges' joyful, immersive David Bowie tribute at Here East

Sound and Vision: inside Jason Bruges' joyful, immersive David Bowie tribute at Here EastHow the artist and lighting designer filled a vast warehouse with balloons, strobes and one of the Thin White Duke’s greatest songs

-

At this seductive Brooklyn club, you can dance the night away under a canopy of plants

At this seductive Brooklyn club, you can dance the night away under a canopy of plantsWith a strict no-photo policy and impeccable design, Green Room is 'supposed to be a haven for the creative class'

-

A Frank Lloyd Wright birdhouse? How a father-daughter company redefined small-scale architecture

A Frank Lloyd Wright birdhouse? How a father-daughter company redefined small-scale architectureFounded by Nima and Mina Yadollahpour, Chirp Company designs architecturally inspired birdhouses for discerning feathered friends