Features

Latest

-

Dip into Janu Tokyo hotel, Aman’s sociable new sibling brand

Step inside the Jean-Michel Gathy-designed Janu Tokyo and discover its state-of-the-art wellness facilities

By Jens H Jensen Published

-

Kapwani Kiwanga considers value and commerce for the Canada Pavilion at the Venice Biennale 2024

Kapwani Kiwanga draws on her experiences in materiality for the Canada Pavilion at the 60th Venice Biennale

By Hannah Silver Published

-

Salone del Mobile 2024: what to see at the fair and at Milan Design Week

The Wallpaper* guide to Salone del Mobile 2024 and Milan Design Week (16-21 April), from public installations and new launches, to the most exciting locations open for one week only

By Rosa Bertoli Last updated

-

‘Help me go faster’: How Nike Air is priming its athletes for Olympic success

Ahead of the Paris 2024 Olympics, Nike’s chief design officer Martin Lotti opens up to Wallpaper* about its latest high-performance sneakers, developed alongside world-leading athletes and honed using AI technology

By Ann Binlot Published

-

Stone Island’s ‘Prototype Research’ exhibition at Milan Design Week is a temple to innovation

At Milan Design Week 2024, Stone Island reveals the latest edition of its ‘Prototype Research’ project, a limited-edition series that pushes fabric innovation to its limits. Here, design director Silvio Rivetti tells Wallpaper* more about this year’s fresco-like installation

By Jack Moss Published

-

Where to eat in Milan: designers’ favourite haunts

Asked where to eat in Milan, local designers Cristina Celestino, Atelier Biagetti, Studiopepe and Palomba Serafini Associati share their favourite coffee, cocktail, lunch and dinner spots

By Sofia de la Cruz Published

-

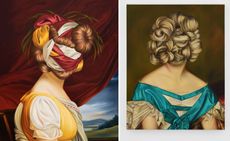

India Mahdavi’s experimental and colourful tiles redefine interior paradigms

India Mahdavi is Japanese brand Alternative Artefacts Danto's first collaborator. At Milan Design Week 2024, they present a collection of tiles which reflect on history and inspires future interiors

By Danielle Demetriou Published

-

Biagetti's Wearable Casa collection is a beautiful mélange of design inspiration

Biagetti's wearable Casa Collection in collaboration with MCM is inspired by an array of urban culture, artificial intelligence and uncommon objects, showcased at Milan Design Week 2024

By Cristina Kiran Piotti Published

-

The story behind Chanel’s iconic handbags, the 2.55 and the 11.12

The liberated spirit of Coco Chanel runs through the house’s most memorable handbags, which are being put back centre stage by current creative director Virginie Viard. Here, Wallpaper* takes a closer look

By Jack Moss Published

-

Google and Chromasonic make sense of colour at Milan Design Week

Google's interactive installation in collaboration with Chromasonic demonstrates how colour influences our perception of the world

By Adrian Madlener Published

-

‘English Folk with Italian Horsepower’: Faye Toogood and Poltrona Frau unveil their collaboration

Poltrona Frau unveils 'Squash', its new collaboration with Faye Toogood, presented during Salone del Mobile 2024 as part of the Italian furniture company's 'Imagine' collection

By Rosa Bertoli Published

-

Venice Art Biennale 2024: a guide to what to see in and around the city

As the Venice Art Biennale kicks off (20 April - 24 November 2024), here is an ever-growing list of what to see in and around Venice.

By Amah-Rose Abrams Published

-

Modernist architecture: inspiration from across the globe

Modernist architecture has had a tremendous influence on today’s built environment, making these midcentury marvels some of the most closely studied 20th-century buildings; check back soon for new additions to our list

By Ellie Stathaki Published

-

‘Fashion Faux Parr’: Martin Parr on taking the sheen off fashion photography

Martin Parr talks to Wallpaper* about his new Phaidon book, ’Fashion Faux Parr‘, which documents his distinct approach to fashion photography – from shooting Gucci on Cannes sunbathers to a Vogue shoot in New York’s Katz Deli

By Zoe Whitfield Published

-

Lanserhof Sylt’s detox programme leaves you ‘glowing and full of energy’

German health resort, Lanserhof Sylt’s ‘Lanserhof Cure’ programme makes a lasting first impression on Nick Vinson

By Nick Vinson Published

-

25 Milan pizza spots recommended by the city's designers

Looking for the best pizza in Milan? We map the best spots with help from the city's local designers, curators and creative directors.

By Rosa Bertoli Published

-

Watches and Wonders 2024: all the highlights from the Geneva event

Discover the watches at the year's biggest watch event, Watches and Wonders

By Hannah Silver Last updated

-

Discover the watch bracelets of the future at Watches and Wonders 2024

A new space at Watches and Wonders 2024, the LAB, turns its gaze to the future of watchmaking

By Hannah Silver Published

-

Tsatsas teams up with a cult 1990s designer for collection in leather and lace

German leather goods brand Tsatsas has united with Kostas Murkudis, who began his career as first assistant to Helmut Lang, on a capsule collection of clothing and accessories constructed entirely from leather and lace

By Jack Moss Published

-

The 12 design-worthy Milan hotels we are checking into now

Explore the best of Milan hotels, from the neo-classical Palazzo Cordusio to Armani and Bulgari’s high-bar luxury retreats

By Sofia de la Cruz Last updated

-

John Akomfrah explores the sonic for the British Pavilion at the Venice Biennale 2024

We spoke with John Akomfrah ahead of the 60th Venice Biennale on what to expect from his British Pavilion

By Hannah Silver Published

-

Ibrahim Mahama tells us why he has covered the Barbican in pink fabric

Ibrahim Mahama's 'Purple Hibiscus' has transformed the Barbican’s Lakeside Terrace

By Hannah Silver Published

-

All the Rolex watches launched at Watches and Wonders 2024

This year, Rolex watches marry past design codes with modern technology

By Hannah Silver Published

-

Fragranced watches are the future, predicts Vacheron Constantin at Watches and Wonders 2024

Vacheron Constantin unites with fashion designer Yiqing Yin on fragranced concept watch ‘Égérie – The Pleats of Time’

By Hannah Silver Published

-

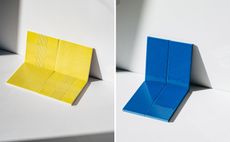

Hermès Cut watches are launched against Erin O’Keefe’s colourful set at Watches and Wonders 2024

Erin O’Keefe has created a sculptural scenography for Hermès at Watches and Wonders 2024

By Hannah Silver Published

-

Rimowa’s ‘Hammerschlag’ design is inspired by a Nils Frahm piano piece

Rimowa and Nils Frahm hammer down on expressive techniques to create the ‘Hammerschlag’ carry case and cabin bag

By Caragh McKay Published

-

Gavin Turk subverts still-life painting and says: ‘We are what we throw away’

Gavin Turk considers wasteful consumer culture in ‘The Conspiracy of Blindness’ at Ben Brown Fine Arts, London

By Rowland Bagnall Published

-

The Met’s ‘The Real Thing: Unpacking Product Photography’ dissects the avant-garde in early advertising

A new exhibition at The Metropolitan Museum of Art in New York explores the role of product photography and advertising in shaping the visual language of modernism

By Zoe Whitfield Published

-

First look at Moncler’s blockbuster new exhibition, which turns Milan Central Station into an immersive public gallery

Wallpaper* takes an exclusive look at Moncler’s new Jefferson Hack-curated exhibition, which features portraits of an eclectic cast of international creatives, including artist Daniel Arsham, musician Rina Sawayama and make-up artist Isamaya Ffrench

By Jack Moss Published