Features

Latest

-

Gerhard Richter unveils new sculpture at Serpentine South

Gerhard Richter revisits themes of pattern and repetition in ‘Strip-Tower’ at London’s Serpentine South

By Hannah Silver Published

-

Dark watches show it’s time to embrace an inky palette

Discover new dark watches from brands including Audemars Piguet, Omega, Chanel and Tudor

By Hannah Silver Published

-

Neuraé: meet the new French skincare brand that can change your emotions

Neuraé is a new neuroscientific skincare brand harnessing the connection between the skin and the brain

By Hannah Tindle Published

-

Meet the Turner Prize 2024 shortlisted artists

The Turner Prize 2024 shortlisted artists are Pio Abad, Claudette Johnson, Jasleen Kaur and Delaine Le Bas

By Hannah Silver Published

-

London gallery Incubator’s six emerging artists to see in spring 2024

Incubator's spring programme features six artists in consecutive two-week solo shows at the London, Chiltern Street gallery

By Mary Cleary Published

-

Why Bollinger’s La Grande Année 2015 champagne is worth celebrating

Champagne Bollinger unveils La Grande Année 2015 and La Grande Année Rosé 2015, two outstanding cuvées from an exceptional year in wine-making

By Melina Keays Published

-

Cult 1960s boutique Granny Takes A Trip gets a sustainable reboot

Founded on King’s Road in 1966, ‘radically creative’ fashion store Granny Takes A Trip is being reimagined for a new generation. Dal Chodha takes a closer look

By Dal Chodha Published

-

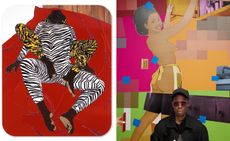

Artist Mickalene Thomas wrestles with notions of Black beauty, female empowerment and love

'Mickalene Thomas: All About Love’, a touring exhibition, considers Black female representation

By Hannah Silver Published

-

The moments fashion met art at the 60th Venice Biennale

The best fashion moments at the 2024 Venice Biennale, with happenings from Dior, Golden Goose, Balenciaga, Burberry and more

By Jack Moss Published

-

Venice Art Biennale 2024: a guide to what to see in and around the city

As the Venice Art Biennale kicks off (20 April - 24 November 2024), here is an ever-growing list of what to see in and around Venice.

By Amah-Rose Abrams Last updated

-

Montblanc’s leather goods evolution offers peak style

Montblanc takes design inspiration from its iconic writing archive for new collections of leather goods

By Simon Mills Published

-

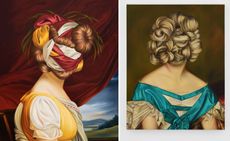

The cosmos meets art history in Vivian Greven’s New York exhibition

Vivian Greven’s ‘When the Sun Hits the Moon’, at Perrotin in New York City, is the artist’s first solo exhibition in the USA

By Emily McDermott Published

-

Fernando Jorge’s fluid diamond earrings show his curve appeal

Discover Brazilian jewellery designer Fernando Jorge's snake-like silhouettes and graphic shapes

By Hannah Silver Published

-

Salone del Mobile 2024: what to see at the fair and at Milan Design Week

The Wallpaper* guide to Salone del Mobile 2024 and Milan Design Week (16-21 April), from public installations and new launches, to the most exciting locations open for one week only

By Rosa Bertoli Last updated

-

Kembra Pfahler revisits ‘The Manual of Action’ for CIRCA

Artist Kembra Pfahler will lead a series of classes in person and online, with a short film streamed from Piccadilly Circus in London, as well as in Berlin, Milan and Seoul, over three months until 30 June 2024

By Zoe Whitfield Published

-

Loewe’s Jonathan Anderson drafts artists to create 24 extraordinary lamps at Milan Design Week 2024

Loewe creative director Jonathan Anderson commissioned international artists and artisans to explore ‘illumination within the house’ with a series of lamps and lighting installations, shown at a group exhibition at Milan Design Week 2024

By Scarlett Conlon Published

-

What are polynucleotides? Trying the skin injectable made from salmon sperm

Polynucleotides are the latest in skin injectables, containing DNA derived from the gonads of salmon. Wallpaper* Beauty & Grooming Editor Hannah Tindle tries them to discover exactly how they work

By Hannah Tindle Published

-

Josèfa Ntjam on her surreal utopias in Venice

Artist Josèfa Ntjam and LAS Art Foundation bring other worlds to life with ‘swell of spæc(i)es’ at Accademia di Belle Arti di Venezia during the Venice Biennale 2024

By Hannah Silver Published

-

Les Lalanne’s surreal world takes over Venice

‘Planète Lalanne’, presented by Ben Brown Fine Arts, takes over Palazzo Rota Ivancich, with a cast of blue hippos, woolly sheep and giant grasshoppers

By Hannah Silver Published

-

At home with Barnaba Fornasetti

Barnaba Fornasetti invites us into Casa Fornasetti, a private residence and creative hub, as he carries on its founder’s perpetual exploration of creativity and design

By Maria Cristina Didero Published

-

Perfumer H has bottled the scent of dandelions blowing in the wind

Perfumer H has debuted a new fragrance for spring, called Dandelion. Lyn Harris tells Wallpaper* about the process of its creation

By Hannah Tindle Published

-

The best fashion moments at Milan Design Week 2024

Scarlett Conlon discovers the moments fashion met design at Salone del Mobile and Milan Design Week 2024, as Loewe, Hermès, Bottega Veneta, Prada and more staged intriguing presentations and launches across the city

By Scarlett Conlon Published

-

In Van Cleef & Arpels’ high jewellery, the archival meets the au courant

Van Cleef & Arpels pays tribute to its rich heritage with a captivating high jewellery collection

By Hannah Silver Published

-

Aindrea Emelife on bringing the Nigerian Pavilion to life at the Venice Biennale 2024

Curator Aindrea Emelife has spearheaded a new wave of contemporary artists at the Venice Biennale’s second-ever Nigerian Pavilion. Here, she talks about what the world needs to learn about African art

By Ugonna-Ora Owoh Published

-

Inside Valentino’s glamorous new Sloane Street store, inspired by the art of haute couture

The latest in Valentino’s ‘The New Maison’ store concept opens on London’s Sloane Street this week, offering an enveloping marble and carpet-clad space of ‘intimacy and uniqueness’

By Jack Moss Published

-

Thom Browne shows how to make the perfect bed with theatrical performance at Milan Design Week 2024

American fashion designer Thom Browne makes his Milan Design Week debut with a new homeware collection created in collaboration with historic linen company Frette

By Scarlett Conlon Published

-

Cosmoprof 2024: the beauty innovations discovered by Wallpaper*

Cosmoprof invited Wallpaper* to discover the latest innovations in beauty, from tech devices to natural skincare

By Hannah Tindle Published

-

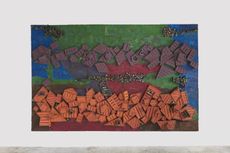

Elias Sime reflects on the destructive nature of technology in Venice

In his solo show ‘Elias Sime: Dichotomy ፊት አና ጀርባ’ at the Venice Biennale 2024, the artist spotlights technology's destructive nature for humans and the environment

By Gameli Hamelo Published

-

Paris’s Musée des Arts Décoratifs celebrates avant-garde jewellery design

'Fashion, Design, Jewellery Exhibit' is the new transdisciplinary exhibition at Paris’s Musée des Arts Décoratifs

By Minako Norimatsu Published